0.08T Gas Steam Bolier for Balloon Production

Latex is the shape of a balloon. Latex preparation needs to be carried out in a vulcanization tank. The steam generator is connected to the vulcanization tank, and the natural latex is pressed into the vulcanization tank. After adding an appropriate amount of water and auxiliary material solution, the steam generator is turned on, and the high-temperature steam is heated along the pipeline. The water in the vulcanization tank reaches 80°C, and the latex is indirectly heated through the jacket of the vulcanization tank to fully mix it with water and auxiliary material solutions.

Latex configuration is the preparatory work for balloon production. The first step in balloon production is mold washing. Balloon molds can be made of glass, aluminum, stainless steel, ceramics, plastic, etc.; mold washing is to soak the glass mold in hot water. The temperature of the water pool heated by the Si steam generator is 80°C-100°C, so that the glass mold can be cleaned and put into production conveniently.

After the mold washing is completed, the mold is coated with calcium nitrate, which is the latex infiltration stage. The dipping process of the balloon requires the glue temperature of the dipping tank to be kept at 30-35°C. The gas steam generator quickly heats up the dipping tank, and the temperature is controlled to make the latex adhere perfectly. on glass molds.

Afterwards, remove the moisture on the surface of the balloon to take it out of the mold. At this time, steam drying is needed. The heat generated by the steam generator is even and controllable, and it will not be too dry. The high-temperature steam with suitable humidity can evenly and quickly dry the latex. The qualified rate of the balloon is over 99%.

In the entire production line of the balloon, the steam generator plays an important role. It can heat up rapidly according to the process requirements, and keep the temperature at a constant temperature. The high-temperature steam has a significant effect on improving the quality and production efficiency of the balloon.

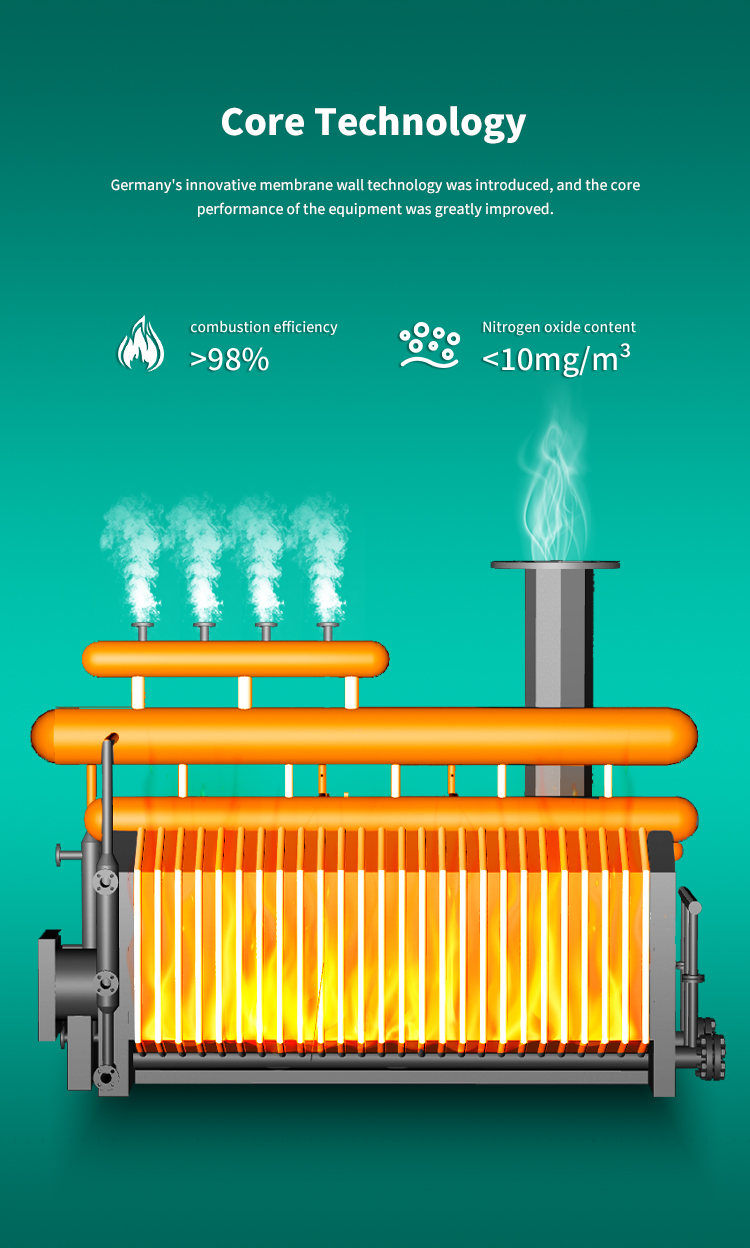

The thermal efficiency of the Nobeth gas steam generator is as high as 98%, and will not decrease with the use of time. The new combustion technology achieves low exhaust gas temperature, high efficiency and low energy consumption.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top