0.3T Gas Steam Boiler equipped the pot for heating

The steam jacketed pot has the characteristics of low energy consumption, high safety performance, more uniform heating, and more importantly, higher thermal efficiency, and is very popular in the food processing industry.

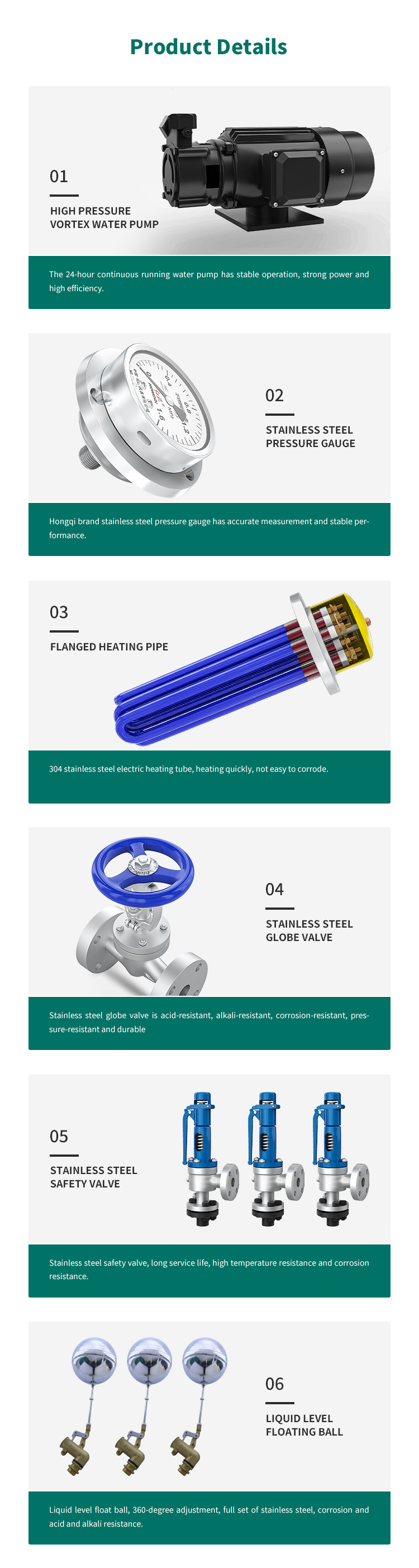

When using a steam jacketed boiler, it must be equipped with a corresponding steam generator, an external intelligent gas steam generator, and the steam temperature, steam pressure, and steam size can be adjusted, which is also the first choice of many enterprises. The parameters of the steam jacketed boiler generally provide the working steam pressure, such as 0.3Mpa, the 600L jacketed boiler needs about 100kg/L evaporation, the 0.12 ton gas module steam generator, the maximum steam pressure is 0.5mpa, the module can operate independently, and the energy consumption of natural gas 4.5-9m³/h, on-demand steam supply, natural gas is calculated at 3.8 yuan/m³, and the gas cost per hour is 17-34 yuan.

The blanching machine can be used for heating food, blanching vegetables, and is also very common in stuffing food processing. The blanching machine is used in conjunction with the steam generator, which plays an important role in disinfection and sterilization while blanching vegetables and food, and completes production tasks safely and efficiently.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top