0.5T Gas Oil Steam Boiler with all the accessories

In the field of food production and processing, the high-temperature steam of steam generators is widely used in various mechanical equipment, such as cleaning, crushing, shaping, mixing, cooking and packaging. The energy of high-temperature and high-pressure steam provides power for every step in food processing. At the same time, its sterilization and disinfection effects build a solid barrier for food safety.

Through the high-temperature steam generated by the steam generator, various steps in the food processing process can be carried out smoothly. This clean and efficient energy not only provides necessary power for mechanical equipment, but also ensures the hygiene and safety of food during processing. In addition, the sterilization effect of high-temperature steam is of great significance for ensuring food safety, and undoubtedly sets new safety standards for the food production and processing industry.

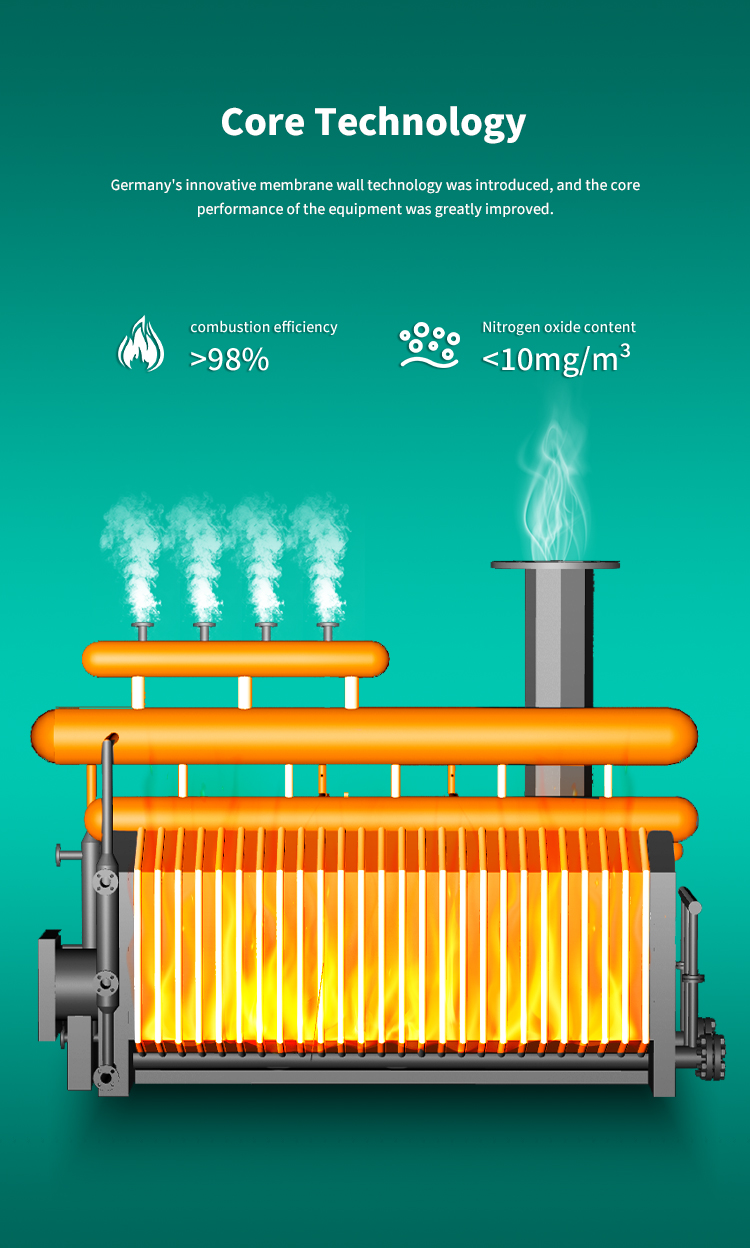

Not only that, the steam generator is also energy-saving and environmentally friendly. It uses advanced energy utilization technology to not only generate steam efficiently but also reduce energy consumption and emissions. This not only contributes to environmental protection, but also makes our lives healthier and more comfortable.

It can be seen that the emergence of food processing steam generators is undoubtedly a perfect combination of taste and technology.

Case: Dezhou City, Shandong Province One AH360kw. Among them, the 360kw equipment is mainly used for cooking, sterilization and sterilization before product canning, while the 216kw equipment is used to heat a jacketed pot containing 800 kilograms of raw materials, and then boil the bone paste for 4 hours. There is also a cooking tank inside To cook 2.7 tons of hot pot base, the temperature can reach 80-85°C during operation, and it needs to be heated for 6 hours and kept under pressure for 20 minutes.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top