0.6T Low Nitrogen Steam Boiler

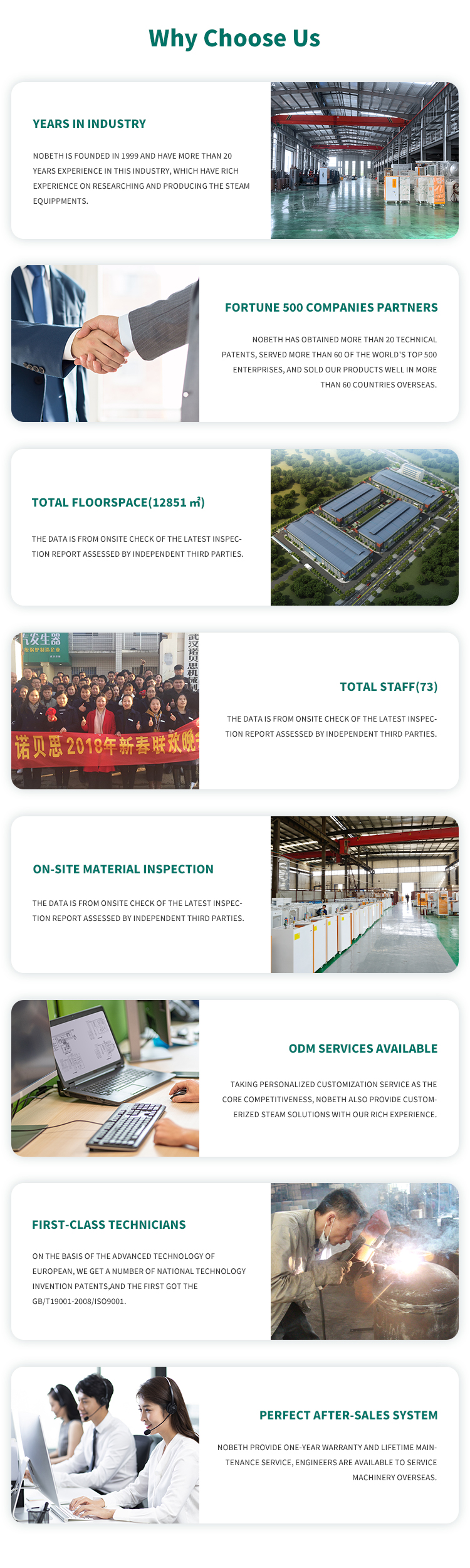

On the other hand, strict environmental protection policies also encourage steam generator manufacturers to carry out continuous technological innovation. Traditional coal-fired boilers have gradually withdrawn from the historical stage, and new electric heating steam generators, low nitrogen steam generators and ultra-low nitrogen steam generators have become the main force in the steam generator industry.

Low-nitrogen combustion steam generator refers to a steam generator with low NOx emissions during fuel combustion. The NOx emission of traditional natural gas steam generator is about 120~150mg/m3, while the emission of low nitrogen steam generator is about 30~

80mg/m2. NOx emissions below 30mg/m3 are generally called ultra-low nitrogen steam generators.

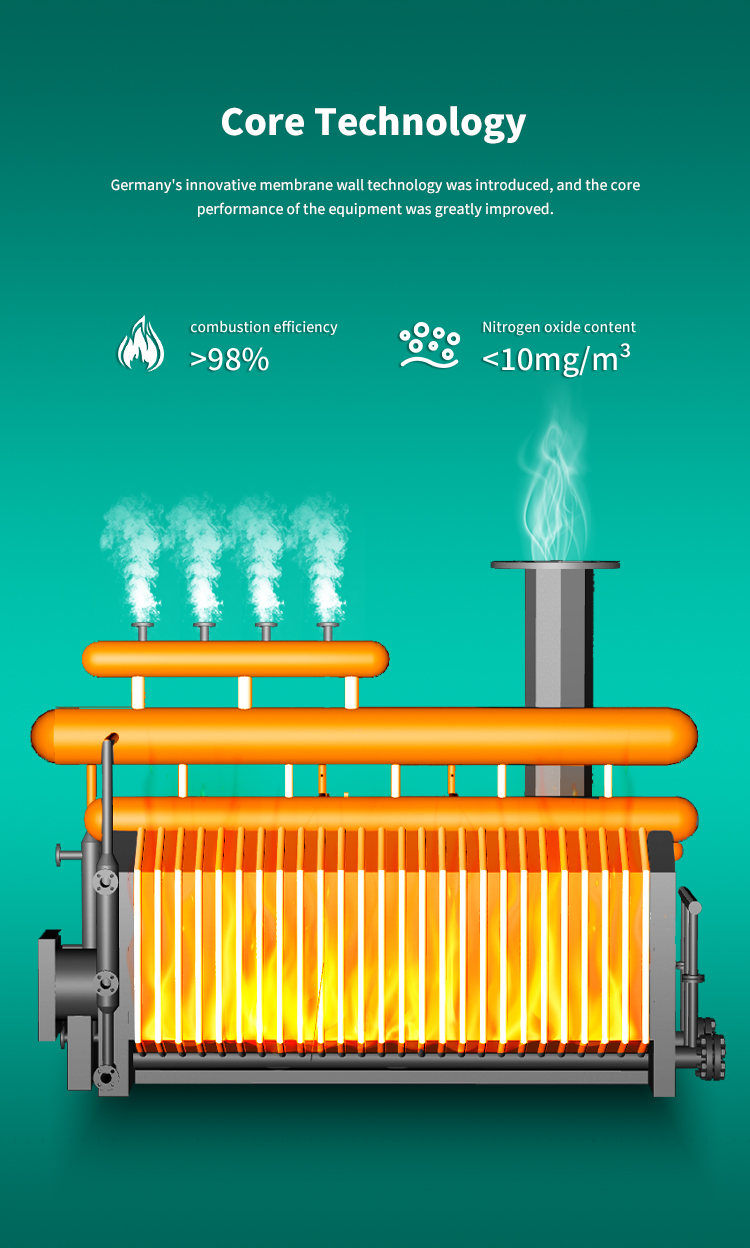

In fact, the low-nitrogen conversion of the boiler is a flue gas recirculation technology, which is a technology to reduce ammonia oxide by reintroducing part of the boiler flue gas into the furnace and burning it with natural gas and air. By using flue gas recirculation technology, the combustion temperature in the core area of the boiler is reduced and the excess air ratio remains unchanged. Under the condition that the efficiency of the boiler is not reduced, the production of nitrogen oxides is suppressed, and the purpose of reducing the emission of nitrogen oxides is achieved.

In order to test whether the nitrogen oxide emission of low-nitrogen steam generators can meet the emission standards, we have carried out emission monitoring on low-nitrogen steam generators on the market, and found that many manufacturers sell ordinary steam equipment under the slogan of low-nitrogen steam generators, cheat consumers with low prices.

It is understood that normal low-nitrogen steam generator manufacturers and burners are imported from abroad, and the cost of a single burner is as high as tens of thousands of dollars. Consumers are reminded not to be tempted by low prices when purchasing! In addition, check the NOx emission data .

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top