0.8T Gas steam boiler for Curing of Concrete Pouring

Steam curing is an indispensable link in the production and processing of cement products. It is not only related to the stability of product quality, but also directly affects the production efficiency, production cost and energy consumption of concrete. Not only in cold winter, concrete needs to be heated frequently, but in hot summer, in order to avoid cracks caused by excessive temperature difference between inside and outside or constant temperature, concrete needs steam curing. Steam curing of cement products combined with concrete curing steam generator is a necessary means. From precast beam field construction to formwork splicing, beam pouring, steam curing and other production stages, concrete precast components need to have strict operational requirements and specifications, especially in the curing stage. In order to ensure the firmness and durability of the building facilities, it is especially important to maintain the concrete components by insisting on using the concrete curing steam generator. The use of concrete curing steam generator can provide suitable hardening temperature and humidity for concrete hardening, speed up the construction process, and ensure the safety and quality of prefabricated beams. The most important thing is that the steam generator for concrete maintenance can be adapted to local conditions according to materials, processes, and equipment. On the premise of ensuring the release strength, minimize residual deformation and shorten the curing cycle, which is the guiding ideology for establishing a curing system.

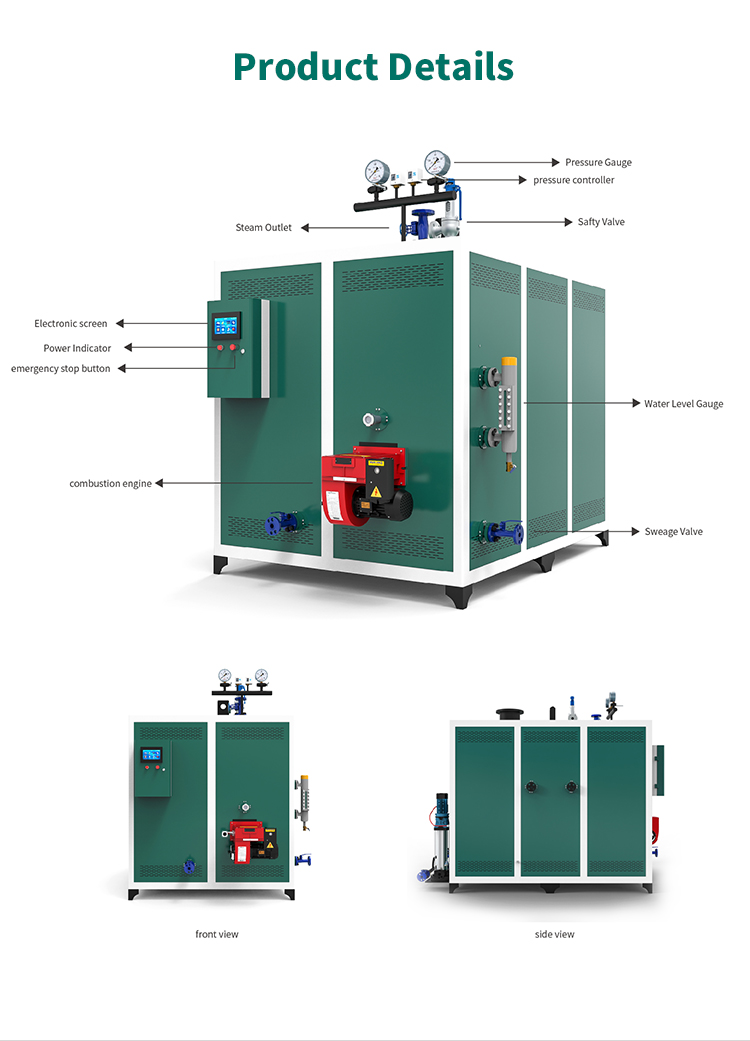

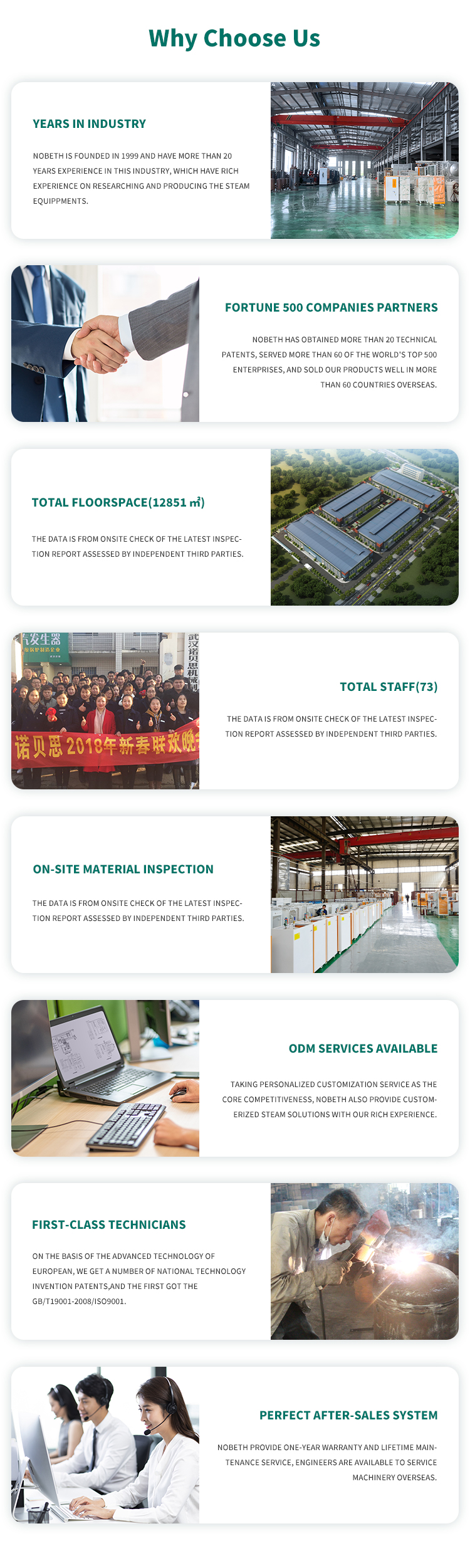

Nobeth steam generator has fast steam production, sufficient steam volume, water and electricity separation, high safety performance, and one-button operation, which is convenient and quick, and improves the efficiency of production and maintenance.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top