1 ton gas steam generator for Biological Technology

Equipment size: The larger the rated evaporation or rated power of the steam generator, for example, a steam generator with an evaporation capacity of 0.5 tons per hour is cheaper than a steam generator with an evaporation capacity of 2 tons. Some equipment nameplates show that the evaporation capacity is 1 ton, but the actual evaporation capacity is less than 1 ton. Some steam generators contain too much water, resulting in high real operating costs.

Temperature and pressure: The conventional type of Noves steam generator is 0.7Mpa, and the temperature can reach 171 degrees Celsius. It is a slightly superheated steam generator with low gas consumption and stable operation. The pressure of customized models with special requirements can reach up to 10Mpa, and the temperature can reach up to 1000°C. Different temperatures usually correspond to different pressures. The higher the temperature, the greater the pressure required and the higher the purchase price.

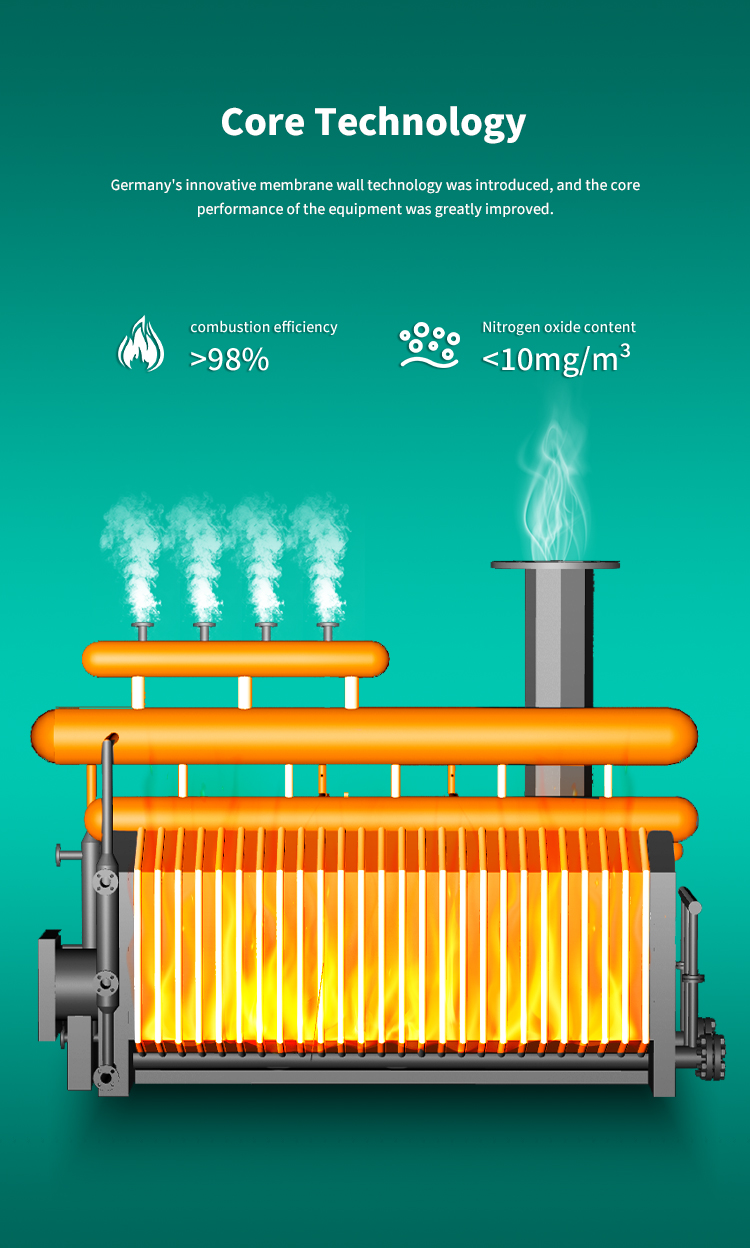

Fuel: Different types of steam generators require different fuels, such as electric heating, fuel oil, gas, biomass pellet combustion, coal combustion, etc. Generally speaking, the equipment structure of steam generator fuel oil and gas with the same evaporation capacity is complicated, and the purchase price is relatively high. Secondly, the price of electric heating steam generators burning biomass and coal is relatively low, but pollution emissions are difficult to control and the scope of application is narrow.

Material quality and component configuration: steam generators can be divided into high-end products and low-end products, and the quality of raw materials used and the configuration of components are also different. Some use stainless steel, some use national standard GB3078 boiler steel, and some use imported components such as German Dongsi valve group. The important components of Noves are all imported brands of leading brands in the industry, which ensures the stability and service life of the equipment.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top