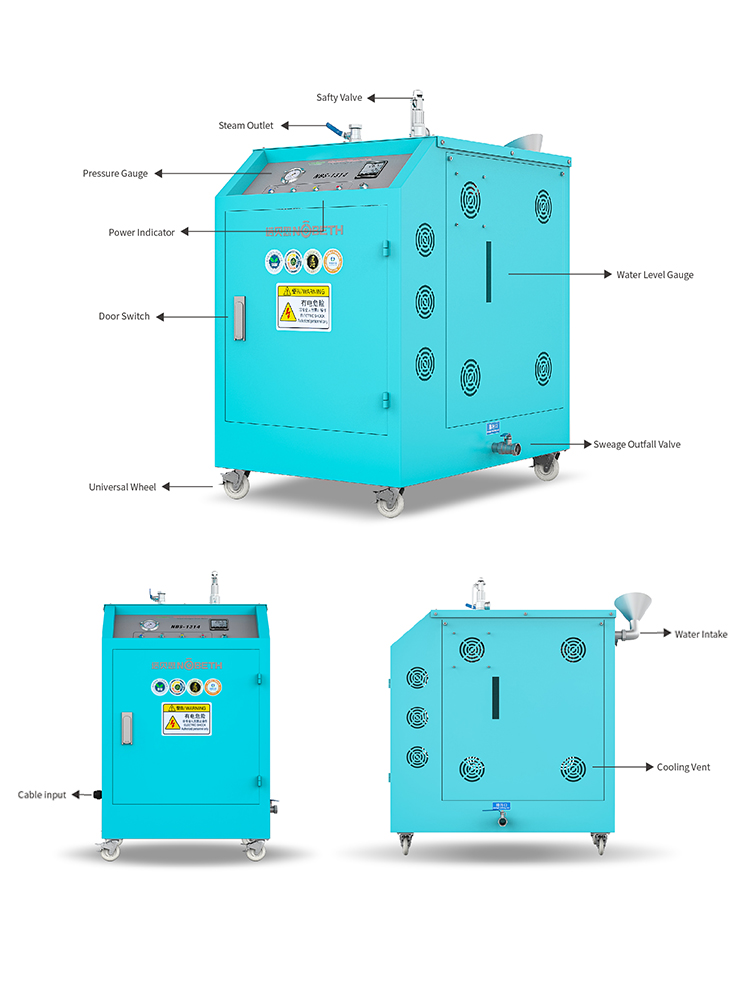

12kw Small Electric Steam Generator for lab

When the electric steam generator leaves the factory, the staff should carefully check whether the physical object is completely consistent with the quantity specified in the list, and must ensure the integrity of the equipment. After arriving at the installation environment, the equipment and components need to be placed on a flat and spacious ground first to avoid damage to the brackets and pipe sockets. Another very important point is that after the electric steam generator is fixed, it is necessary to carefully check whether there is a gap where the boiler and the base are in contact, to ensure a tight fit, and to fill the gap with cement. During installation, the most important component is the electrical control cabinet. It is necessary to connect all the wires in the control cabinet to each motor before installation.

Before the electric steam generator is officially put into use, a series of debugging work is required, and the two key steps are raising the fire and supplying gas. After a comprehensive inspection of the boiler, there are no loopholes in the equipment before raising the fire. During the heating process, the temperature must be strictly controlled, and the temperature should not increase too fast, so as to avoid uneven heating of various components and affect the service life. At the beginning of the air supply, the pipe heating operation must be carried out first, that is, the steam valve should be slightly opened to allow a small amount of steam to enter, which has the effect of preheating the heating pipe, and at the same time, pay attention to whether the components are operating normally. After the above steps, the electric steam generator can be used normally.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top