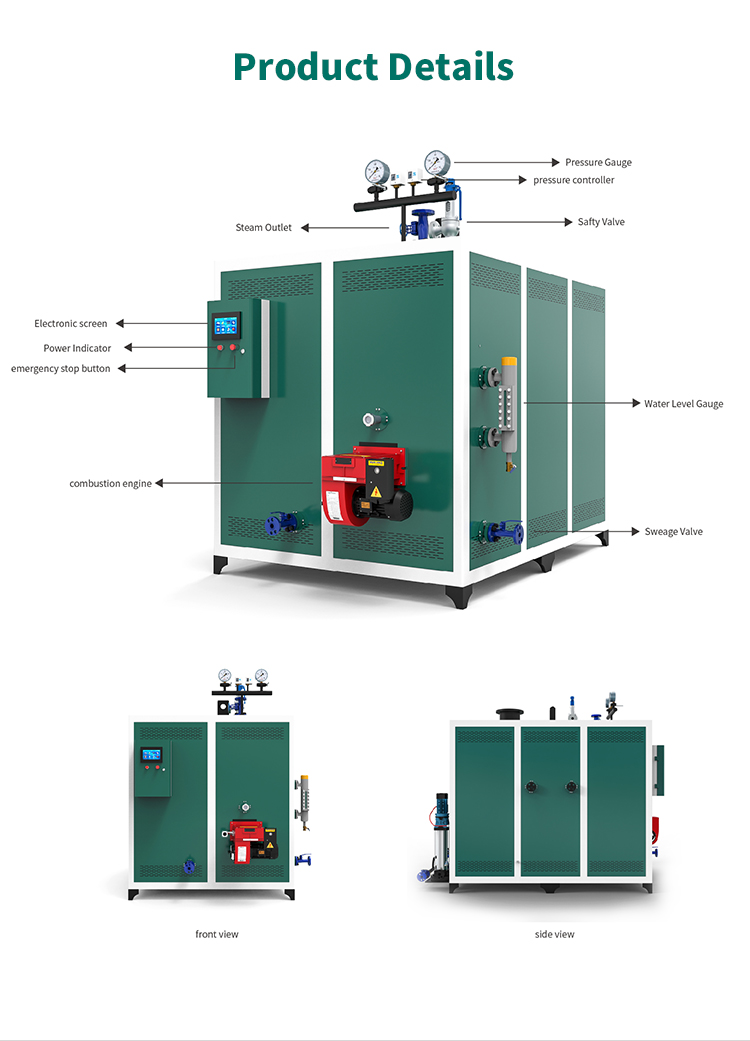

2 Ton fuel gas steam generator with membrane wall structure

The equipment can also effectively recover the heat of boiler sewage: through heat exchange, the heat of continuous sewage can be used to increase the feed water temperature of deoxygenated water, so as to achieve the purpose of energy saving of natural gas steam boilers.

Nobeth membrane wall fuel gas steam generator manufacturer stated that reducing the exhaust temperature of natural gas steam boilers: reduce the exhaust temperature of the boiler and effectively use the waste heat generated in the exhaust. The efficiency of ordinary boilers is 85-88%, and the exhaust gas temperature is 220-230°C. If the economizer is set to utilize the heat of the exhaust gas, the temperature of the exhaust gas will drop to 140-150°C, and the efficiency of the gas steam generator can be increased to 90-98%.

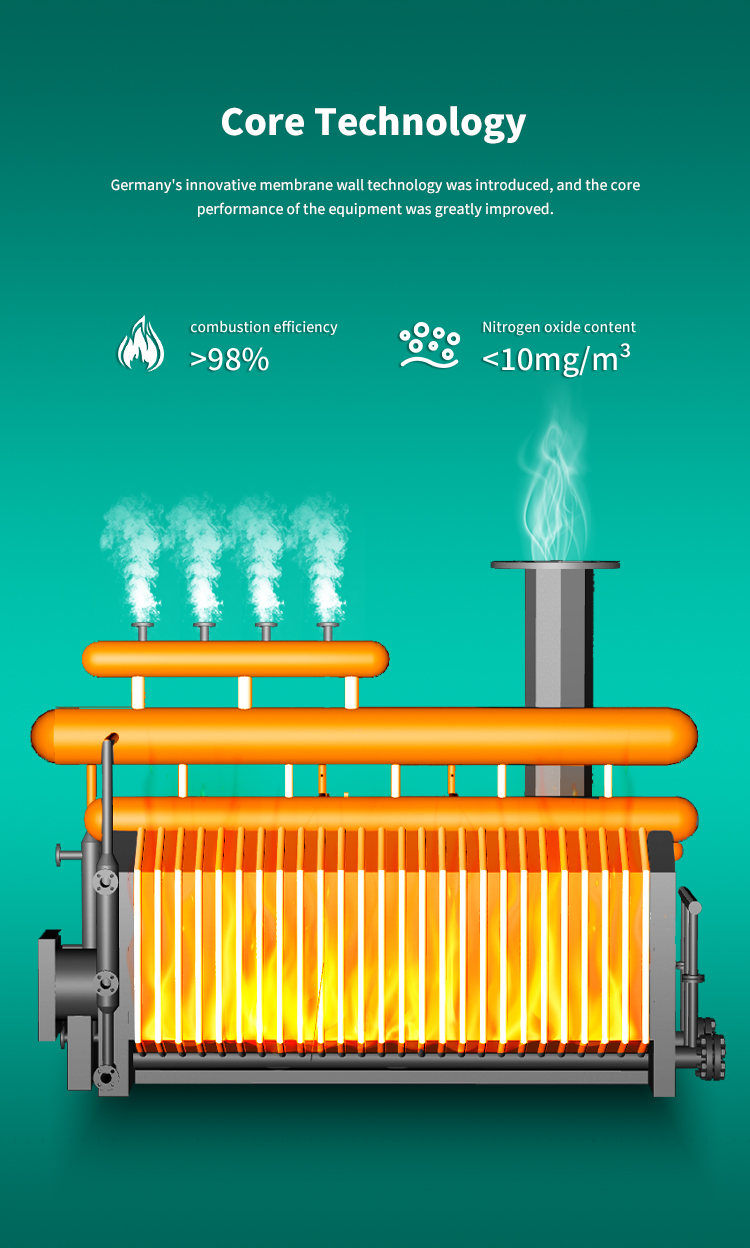

Nobeth membrane wall fuel gas steam generator introduces German membrane wall innovation technology, and the core performance of the equipment is greatly improved. Compared with general fuel gas steam generators, it has the following advantages:

1. Good sealing performance, strong shock resistance and damage prevention

(1) It is made of wide steel plate sealed and welded to avoid air leakage and gurgling smoke, and is more environmentally friendly

(2) The steel plate is integrally welded, with strong shock resistance, which effectively prevents damage caused during boiler movement

2. Thermal efficiency>95%

Honeycomb heat exchange device and steam waste heat condensation recovery device

3. High energy saving and thermal efficiency

There is no furnace wall, the heat dissipation coefficient is small, and the vaporization phenomenon of ordinary boilers is eliminated, and the energy saving is 5% compared with ordinary boilers.

4. Safe and reliable

With multiple safety protection technologies such as high temperature, high pressure, and water shortage, self-inspection and self-inspection + third-party professional inspection + official authority supervision + safety and commercial insurance, one machine, one certificate, more secure.

5. High efficiency and energy saving

Equipped with fin tube type 360 degree double return heat exchange device.

6. Fast heating and cooling

There is no furnace wall, all the heat is absorbed by the model wall, and the humidity rises and cools down quickly.

The equipment can be used in many industries and scenarios, and can be applied in concrete maintenance, food processing, biochemical industry, central kitchen, medical logistics, etc.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top