360kw Electric Steam Generator

So, what exactly is it? Generally speaking, according to the “Special Equipment Safety Supervision Regulations” (hereinafter referred to as the “Regulations”): pressure vessels, boilers, elevators and special equipment inspection agencies that require safety performance testing and evaluation before use shall issue test reports and periodic inspection reports in accordance with the law. The scope and period of such documents are: The “Standard” stipulates: If a production ((user) unit discovers any of the following situations during use or maintenance, it shall immediately stop use or eliminate the danger:

(1) The rated working pressure has been reached or the No safety measures have been taken for pressure vessels that have exceeded the design service life (ten years); (2) The safe service life has exceeded but does not meet the requirements of relevant national and local regulations; (3) The design, manufacturing, installation and maintenance do not comply with National regulations and requirements on safety technical specifications; (4) Failure to guarantee the provision of required materials issued by statutory inspection agencies. When special equipment such as pressure vessels or boilers breaks down and needs repair, the relevant responsible persons should immediately stop operation, cut off the power supply and Report to the special equipment inspection agency.

1. During the production process, if a steam generator is used, its safety performance needs to be tested.

Specifically, after the steam generator is installed for the first time, the steam generator is connected to other equipment and pipelines, and then safety performance testing is performed. Specific details include: (1) After the first installation of the steam generator is completed, the entire steam generator needs to be pressure tested and temperature tested; (2) After the installation is completed, the overall temperature also needs to be tested. (2) Pressure testing is required before the steam generator is operated for the first time. (3) Before putting safety facilities such as steam boilers into operation, safety facilities and equipment and pipelines need to be inspected in terms of pressure, speed and position to ensure their safe operation. (4) When conducting pressure tests on newly installed or renovated boilers, they must comply with corresponding safety standards and regulations. Therefore, according to the “Regulations”: For special equipment among special equipment, it refers to special equipment with special regulations in the design, manufacturing, installation, maintenance and production links. For example, products above boilers can be classified as pressure vessels; inspection reports issued by special equipment inspection agencies can also be classified as pressure vessels.

2. For special equipment stipulated in the “Regulations”, corresponding certificates are required, and among them, in accordance with the provisions of the “Regulations”:

(1) Design, manufacturing, installation and maintenance:

(2) Safety performance testing and evaluation of pressure vessels and elevators used before manufacturing or installation.

(3) The safety performance of the boilers and other special equipment used shall not be lower than the safety performance test and evaluation results during the first operation before the safety performance test is carried out during the design and installation period; if the safety status monitoring and evaluation of the boilers and other special equipment is carried out after use , except those confirmed qualified by the special equipment inspection agency.

(4) Periodic inspection:

(5) If laws and administrative regulations stipulate that periodic inspection should be carried out, it should be handled in accordance with relevant procedures.

3. For other types of special equipment, relevant laws and regulations will apply.

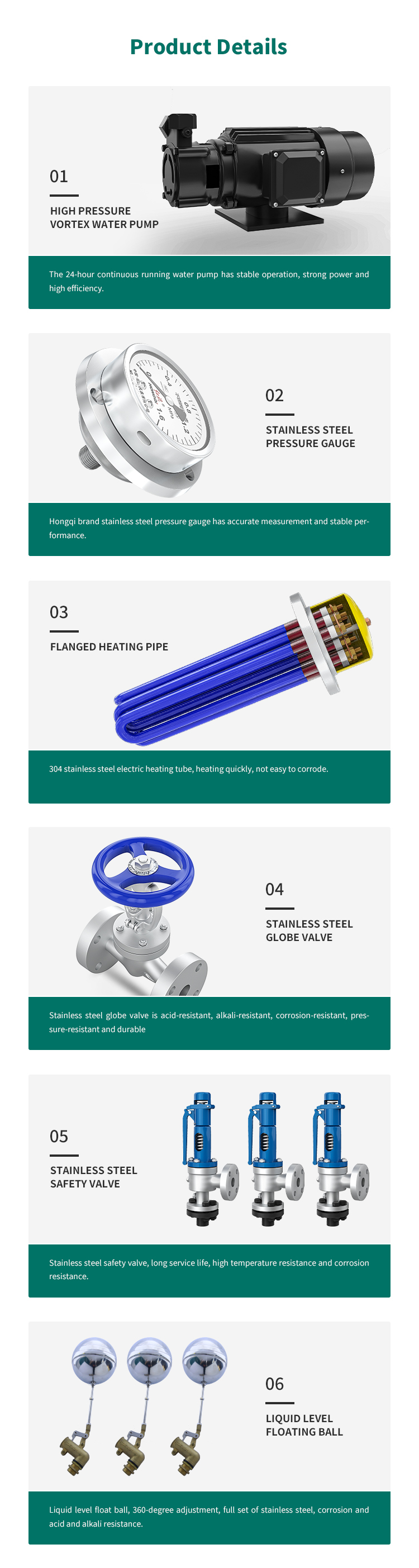

In fact, the reason why there is such a statement is because the steam generator is a common device in our lives. In the eyes of many people, a steam generator is just a simple heating device. In fact, we can see it everywhere in our lives. It is mainly used for hot water, steam heating or power generation. It is composed of a heater, a condenser and related ancillary devices. It is a complete system device, consisting of heater, condenser and water circulation system. The water circulation system includes water tanks and water pumps.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top