36kw Explosion-proof Electric Steam Generator

Generally speaking, in order to ensure heating efficiency and shorten the sterilization interval, the higher the sterilization temperature, the shorter the required sterilization time. There is often a certain degree of inhomogeneity in the detection of steam temperature. At the same time, there is a certain hysteresis and deviation in the detection of temperature. Considering that the temperature and pressure of saturated steam show a one-to-one correspondence, relatively speaking, the detection of steam pressure is more uniform and fast. , so the sterilization steam pressure of the sterilizer is used as the control basis, and the detection of the sterilization temperature is used as the safety guarantee.

In practical applications, steam temperature and sterilization temperature are sometimes different. On the one hand, when the steam contains more than 3% condensed water (the dryness is 97%), although the steam temperature reaches the standard, due to the obstruction of heat transfer by the condensed water distributed on the surface of the steam, in the product, the steam passes through the condensed water film temperature will decrease. Decrease gradually so that the actual sterilization temperature of the product is lower than the sterilization temperature requirement. Especially the boiler water carried by the boiler, its water quality may contaminate the sterilized product. Therefore, it is usually very effective to use Watts DF200 high-efficiency steam-water separator at the steam inlet.

On the other hand, the presence of air has an additional effect on the sterilization temperature of the steam. When the air in the cabinet is not removed or not completely removed, on the one hand, the existence of air will form a cold spot, so that the products attached to the air cannot be sterilized. bacteria temperature. On the other hand, by controlling the vapor pressure to control the temperature, the presence of air creates a partial pressure. At this time, the pressure displayed on the pressure gauge is the total pressure of the mixed gas, and the actual steam pressure is lower than the sterilization steam pressure requirement. Therefore, the steam temperature does not meet the sterilization temperature requirement, resulting in sterilization failure.

Steam superheat is an important factor affecting steam sterilization, but it is often overlooked. EN285 requires that the superheat of the sterilization steam should not exceed 5°C. The principle of saturated steam sterilization is that steam condenses when the product is cold, releasing a large amount of latent heat energy, which increases the temperature of the product; when condensing, its volume shrinks sharply (1/1600), and it can also generate local negative pressure, making the subsequent steam Go deep inside the item.

The properties of superheated steam are equivalent to that of dry air, but the heat transfer efficiency is lower; on the other hand, when superheated steam releases sensible heat and the temperature drops below the saturation point, condensation does not occur, and the heat released at this time is very small. Heat transfer does not meet sterilization requirements. This phenomenon is obvious when the overheat exceeds 5°C. Overheated steam can also cause items to age quickly.

If the steam used is the heat network steam used for power generation, it is itself superheated steam. In many cases, even if the self-contained boiler produces saturated steam, the steam decompression in front of the sterilizer is a kind of adiabatic expansion, making the original saturated steam into superheated steam. This effect becomes apparent when the pressure difference exceeds 3 bar. If the superheat exceeds 5°C, it is best to use a Watt water bath saturated steam device to eliminate the superheat in time.

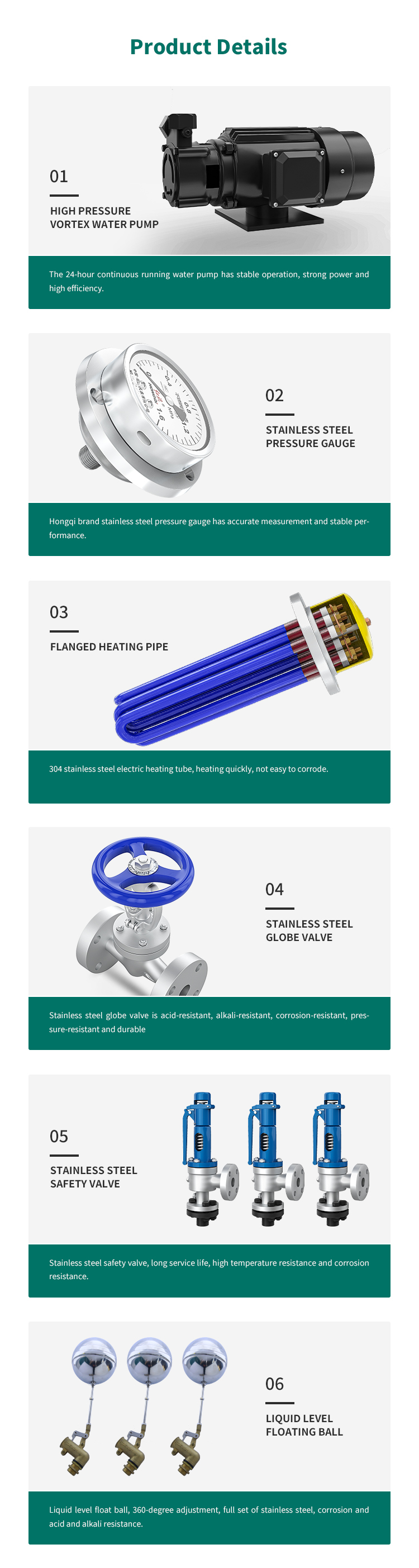

The steam design of the sterilizer includes a steam inlet with a super steam filter, a high-efficiency steam-water separator, a steam pressure regulating valve and a steam trap.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top