48Kw Electric Steam Generator to ensure the safety of railway transportation

In order to remove the accumulated oil stains of diesel locomotives, they need to be disassembled, and then the engine and accessories are put into boiling alkaline water for cleaning.

The high-temperature steam from the steam generator quickly heats the alkaline water in the pool, keeping the alkaline water in a boiling state. The diesel engine and accessories are boiled in the boiling alkaline water for 48 hours, laying the foundation for the subsequent high-pressure washing and thoroughly removing dirt and cleaning agents. .

As an important part of the maintenance of diesel locomotives, boiling and washing train engines and parts is a hard job, which is different from the maintenance of automobiles. Diesel engine bodies, oil and water pipelines, running parts, and sensor accessories of diesel locomotives are all big and small. Baizhong parts are cleaned.

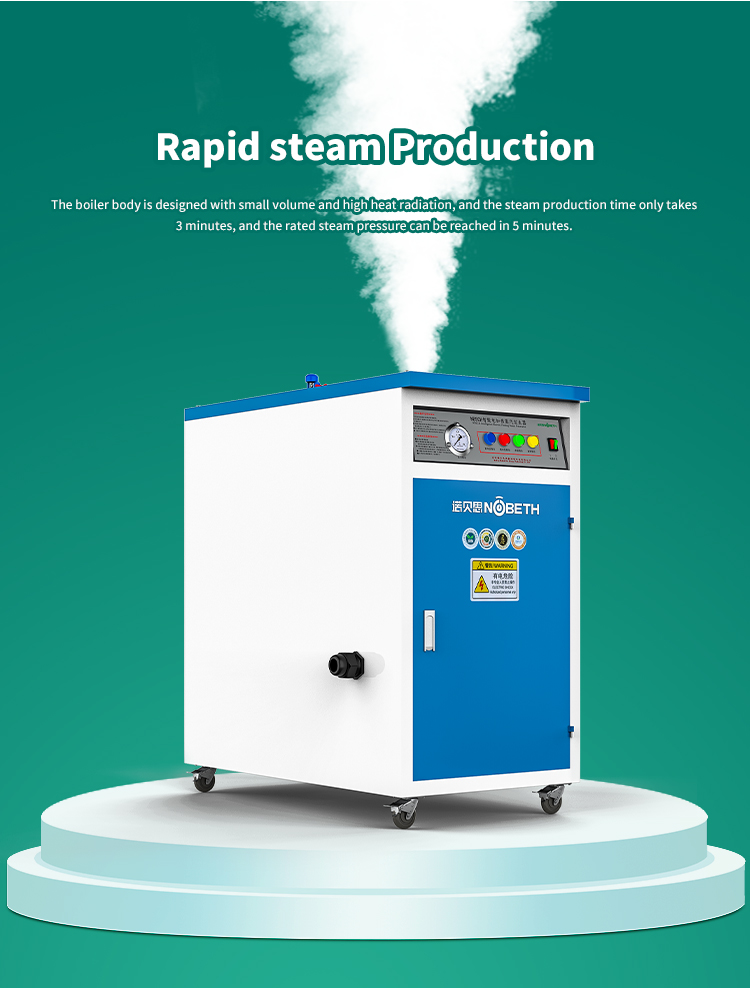

Nobes Electric Heated Steam Generator operates fully automatically, replenishes water automatically, does not need special personnel to take care of it, and can continuously generate steam, which reduces the workload and saves labor costs for the cleaning staff of diesel locomotives.

The maintenance of diesel locomotives plays a very important role, especially for safe driving, but the maintenance work is very complicated. The emergence of electric heating steam generators makes the cleaning and inspection of diesel locomotives better.

The electric heating steam generator can adjust the temperature and pressure according to the actual heat demand, and it is convenient and quick to use. In the long-term use, people can more and more find that the electric heating steam generator is small in size, pollution-free, intelligent control, etc. Use advantages, these advantages are unmatched by traditional boilers.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top