54KW Electric Steam Generator for wood steam bending

Historically, steam bending has been used by wooden boat builders to produce curved ship ribs, by furniture makers for the curved bases of rocking chairs, and by string instrument makers for the curved side panels of stringed instruments. Such as guitar, cello and violin. In a general family workshop, a complete wooden component of a certain size can be made. As long as the steam generator is connected to the airtight steam box, the wooden component can be put into the steam box for shaping.

Using this method, even solid wood planks can be bent into beautifully streamlined curves. And some thinner sheets can become so flexible that they can be knotted without breaking.

So, how does it work? When exposed to hot water vapor in a steam box, the lignans that hold a piece of wood together begin to soften, allowing the wood’s main structure, the cellulose, to be bent into new shapes. When the wood is bent into shape and then returned to normal room temperature and humidity, the lignans begin to cool and regain their original hardness, while preserving the bent shape.

The Jin×Garden Rake Factory located in Hebei Province purchased two Nobles electric heating steam generators for wood shaping. They use steam to heat the wooden handle, which softens the wood after heating, making it easy to shape and straighten. The company connects the steam generator to the steam box, puts the wood that needs to be shaped into it to heat up, the temperature can reach about 120 degrees, and 3 pressures can meet the production requirements. boot.

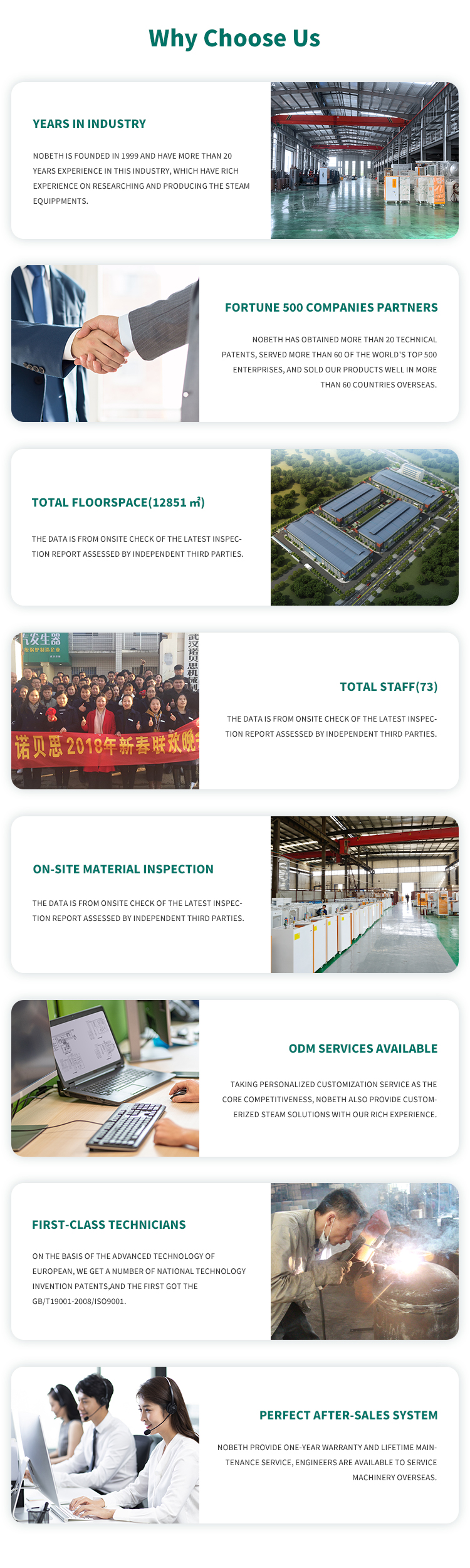

Nobeth Electric Heated Steam Generator produces fast steam and heats up quickly, with one-button control of steam temperature and pressure. It is easy to operate and easy to use, saving customers a lot of time and labor costs during use. At the same time, Nobeth electric heating steam generator does not emit any air pollutants, fully meets the national environmental protection standards, and plays an important role in the wood shaping process.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top