72kw Electric Steam Generator in Oleochemical Industry

1. The vaporization temperature is between 130-150°C

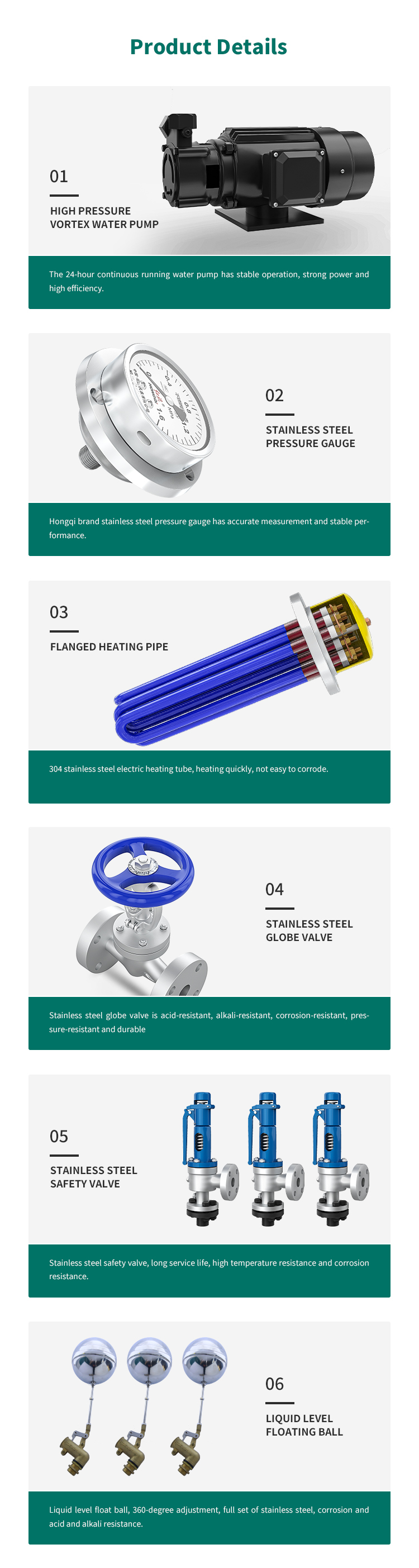

High pressure steam generator can provide higher temperature and pressure is the key to ensure product quality and stable production. Steam generators can be divided into several forms such as single-wall type and combined type. Products generally choose different types of steam generators according to the production process. A steam generator must be able to meet the process requirements. The use and type of steam can be reasonably selected according to the needs of different factories. It can be directly used in oil production, chemical industry and other industries, but if you want to have a good impression of steam, you cannot ignore the use of equipment.

2. The pressure is between 1.2-2.5 MPa

After the oil passes through the steam generator, the oil with a water content of 1%-2% can be quickly turned into smokeless high-temperature and high-pressure oil. After a high temperature and high pressure process, a large amount of high temperature, high pressure, smokeless and odorless steam is produced. The steam generator is mainly an important factor that uses the steam generator of the boiler to realize the work of the equipment. Therefore, manufacturers will use the products produced by steam generators in the production process to provide convenience for the oil and chemical industry. This is because the product can make oil and fat products more hygienic and easy to store.

3. When the pressure is below 2.5 MPal, there will be no tube burst accident in the boiler

In oil production, there are many processes, such as separation, decolorization, filtration, concentration, etc. And this process is also very demanding on steam. Traditional evaporation equipment can only realize water evaporation to generate steam under a certain humidity. These processes all need to use steam. If the steam temperature does not meet certain requirements, there is no guarantee that the boiler will not burst. The use of steam generators in oil production can meet the requirements of oil production. However, some problems have also been encountered during the use of the steam generator, mainly due to scaling problems in the steam water circulation system and the evaporated water system, which can easily lead to unstable combustion of the boiler, tube bursts, and boiler failure to operate normally. There are also some enterprises that use steam generators to produce high-pressure steam with poor quality, waste, and low efficiency. At present, oil production steam generators are more and more used in oil chemical industry, and their application fields are becoming more and more extensive in the oil industry.

4. High system safety factor

In high-temperature and high-pressure steam equipment, the working principle of the steam generator is to use the heat generated by steam and water molecules to condense water vapor into water droplets or water vapor into water or other substances. Water vapor can oxidize with air to produce combustible gases such as hydrogen and carbon monoxide. Like this it can utilize water vapor to absorb a large amount of heat to vaporize water and generate water vapor (water vapour). The calorific value of this high-temperature and high-pressure steam is as high as 800-1200°C: 4-5 times that of metal distillation, so it can effectively avoid potential safety hazards for equipment or systems, and the system has a high safety factor! So the steam generator is a relatively safe steam equipment.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top