Best Quality Fully Automatic Electric AH Heating Steam Generator Help Pasta Fermentation

An important step in the production of steamed buns, bread and other pasta is proofing. Through proofing, the dough is re-gassed and fluffy to obtain the volume required for the finished product, and the finished product of steamed buns and bread has better quality. Making these pastas is inseparable from the proofing of the dough. Intermediate proofing can improve the internal texture structure of the bread, shorten the production cycle, and make it easy to be mechanically formed, which shows its importance. During the proofing time of about a quarter of an hour, it is critical to use the food processing steam generator to adjust the corresponding temperature and humidity.

Temperature, humidity, and time are the main factors that affect the quality of bread proofing. Time can be controlled manually, while temperature and humidity are greatly affected by the environment. Especially in dry winter, it is difficult to naturally proof dough, and equipment is usually required. Auxiliary, steam generator is a good choice.

During the temperature control process, if the temperature is too high, the dough will mature quickly, the gas holding capacity will become worse, and the viscosity will increase, which is unfavorable for subsequent processing; if the temperature is too low, the dough will cool down, resulting in slow rise, thus prolonging the intermediate proofing. time. If it is too dry, there will be hard dough lumps in the finished bread; if the humidity is too high, it will increase the viscosity of the bread skin, thus affecting the next step of shaping.

Good surface finish and overall fluffiness are unique features of successfully proofed bread. Therefore, the proofing conditions must be strictly controlled when making bread. The food processing steam generator has pure steam, and the temperature and humidity are accurately adjusted to create the most suitable environment for intermediate proofing.

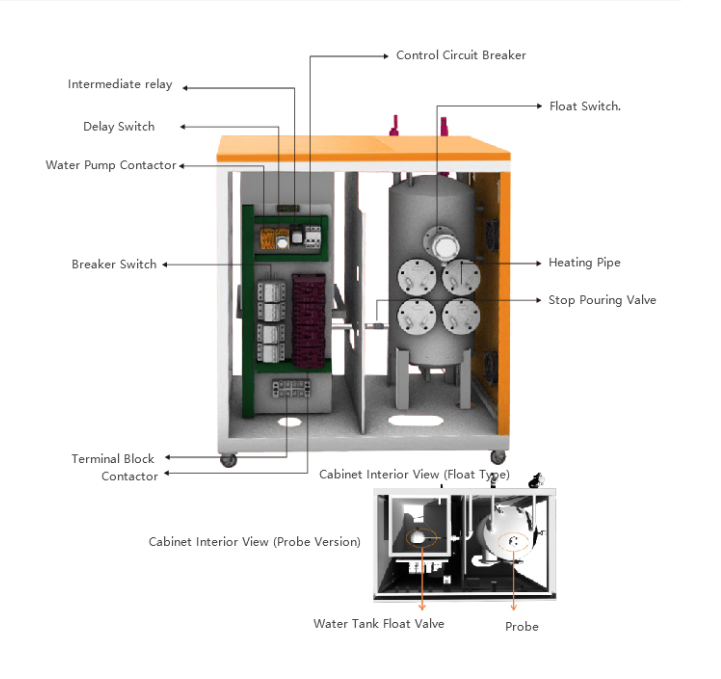

The temperature and pressure of Nobeth steam generator are controllable, so you can freely adjust the steam temperature and steam volume to control the temperature and humidity of the dough proofing room, so that the dough can be proofed to the best state and make more delicious products.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top