CH 48kw Fully Automatic Electric Heating Steam generator makes yuba with high efficiency and good taste

We have all eaten yuba, but do you know how it is made? What are the steps in its production process?

The technological process of yuba: selecting beans → peeling → soaking beans → grinding → pulping → boiling → filtering → extracting yuba → drying → packaging

The following steps are required to use steam:

Boiling pulp and filtering pulp

After the slurry is dried, it flows into the container through the pipeline, blows the slurry with steam, and heats it to 100~110℃. After the slurry is cooked, it flows into the sieve bed through the pipeline, and then the cooked slurry is filtered once to remove impurities and improve the quality.

Extract yuba

After filtering, the cooked slurry flows into the yuba pot and is heated to about 60~70℃. An oily film (oil skin) will form in about 10~15 minutes. Use a special knife to gently cut the film from the middle and divide it into two pieces. Extract separately. When extracting, rotate it by hand into a column shape and hang it on a bamboo pole to form yuba.

Drying packaging

Send the yuba hanging on the bamboo pole to the drying room and arrange them in order. The temperature in the drying room reaches 50~60℃, and after 4~7 hours, the surface of the yuba will turn yellow-white, bright and translucent.

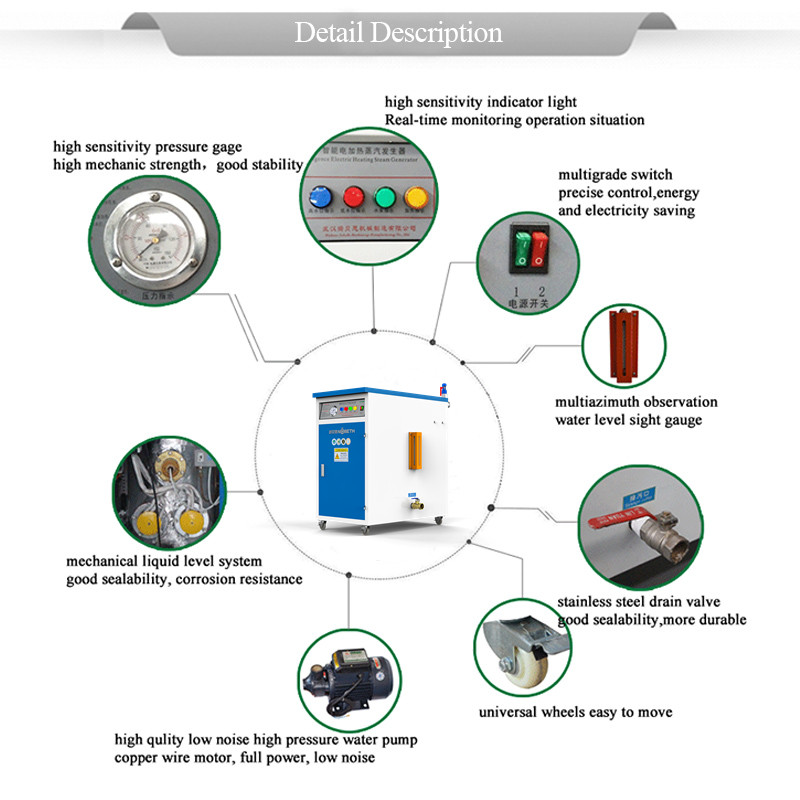

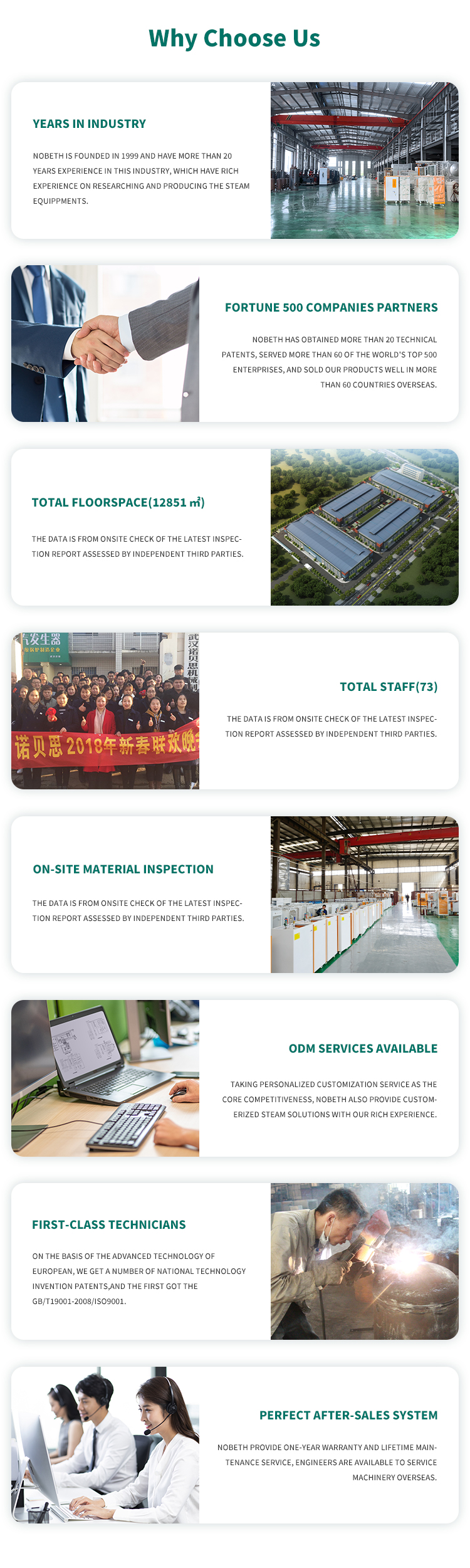

Use a steam generator to perform the next few steps. The traditional heating method in the past was inconvenient to control the temperature and would also affect the shape and taste of the yuba. Use Nobeth steam generator, PLC touch screen controller, or connect to your mobile phone for remote control. You can check the equipment operating status, steam temperature, pressure, etc. on your mobile phone in real time at any time. The steam temperature can be well controlled, and high-temperature steam also plays a good sterilizing effect. This saves worry and is convenient during the production process.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top