0.8T Gas tukunyar jirgi don Maganin Zuba Kankara

Maganin tururi hanya ce mai mahimmanci a cikin samarwa da sarrafa samfuran siminti. Ba wai kawai yana da alaƙa da kwanciyar hankali na ingancin samfurin ba, amma har ma kai tsaye yana rinjayar ingancin samarwa, farashin samarwa da kuma amfani da makamashi na kankare. Ba kawai a lokacin sanyi ba, simintin yana buƙatar dumama, amma a lokacin zafi mai zafi, don guje wa fashewar da ke haifar da yawan zafin jiki tsakanin ciki da waje ko yawan zafin jiki, simintin yana buƙatar maganin tururi. Maganin tururi na kayayyakin siminti haɗe da kankare curing tururi hanya ce da ta dace. Daga precast katako filin gini zuwa formwork splicing, katako zuba, tururi curing da sauran samar matakai, kankare precast aka gyara bukatar da tsananin aiki da bukatun da kuma bayani dalla-dalla, musamman a cikin curing mataki. Domin tabbatar da tsayin daka da karko na kayan gini, yana da mahimmanci musamman don kula da abubuwan da aka gyara ta hanyar dagewa da yin amfani da injin sarrafa tururi na kankare. Amfani da kankare curing tururi janareta iya samar da dace hardening zafin jiki da kuma zafi domin kankare hardening, hanzarta aikin yi, da kuma tabbatar da aminci da ingancin prefabricated katako. Abu mafi mahimmanci shi ne cewa injin tururi don tabbatar da kankare zai iya daidaitawa zuwa yanayin gida bisa ga kayan aiki, matakai, da kayan aiki. Dangane da batun tabbatar da ƙarfin sakin, rage saura nakasar da gajarta zagayowar waraka, wanda shine jagorar akida don kafa tsarin warkarwa.

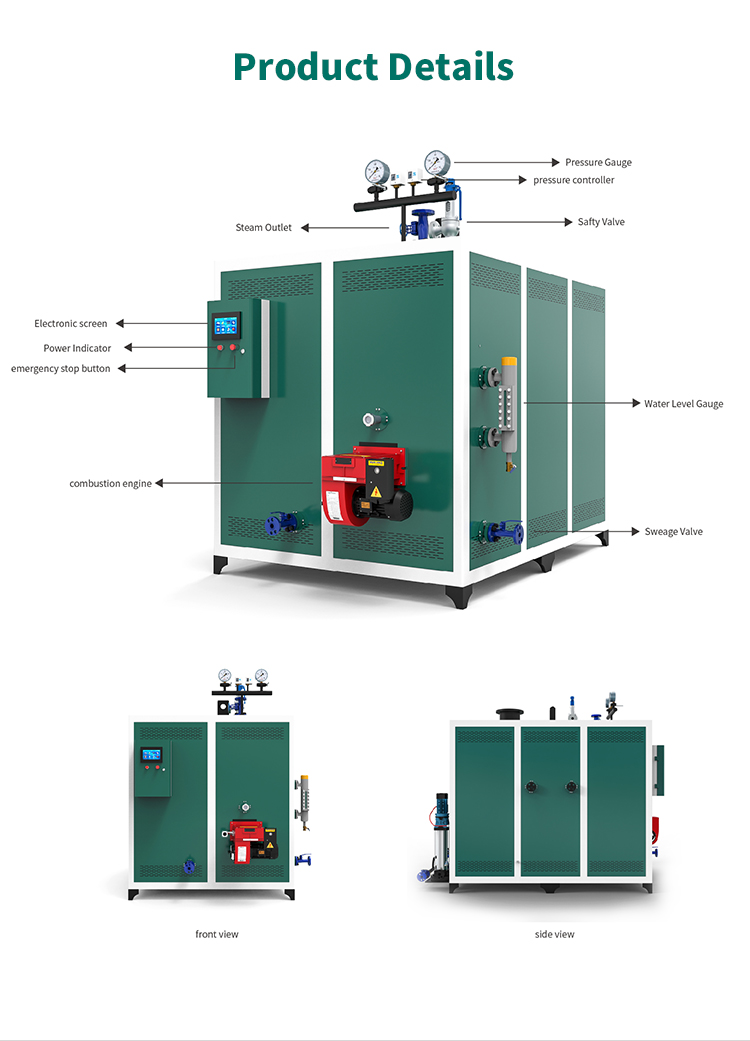

Nobeth tururi janareta yana da sauri samar da tururi, isasshen tururi girma, ruwa da wutar lantarki rabuwa, high aminci yi, da kuma daya-button aiki, wanda shi ne dace da sauri, da kuma inganta yadda ya dace na samarwa da kuma kiyayewa.

Rukunin samfuran

-

Imel

-

Waya

-

WhatsApp

-

Sama