0.3t Ib puag ncig tus phooj ywg Gasoil Chav Generator

Cov yam ntxwv ntawm kev ua haujlwm ntawm roj nkev generator:

1. Cov qauv tsim sab hauv ntawm lub tshuab hluav taws xob roj hluav taws xob sib txawv: qhov dej ib txwm muaj thiab cov dej ntim ntawm cov khoom siv no tsawg dua 30L, uas yog nyob rau hauv qhov kev soj ntsuam tsis muaj tus qauv, yog li tsis tas yuav thov daim ntawv pov thawj siv boiler, tsis tas yuav tuav daim ntawv tso cai ua haujlwm, tsis muaj kev tshuaj xyuas txhua xyoo, tsis muaj cov neeg ua haujlwm puv sijhawm.

2. Superiority ntawm chav: Lub cub tawg yog nruab nrog ib tug built-in steam-dej separator, uas daws cov teeb meem ntev ntawm chav nqa dej, thiab tseem ua kom lub superiority ntawm chav. Chav tuaj yeem tsim sai sai hauv 3 feeb.

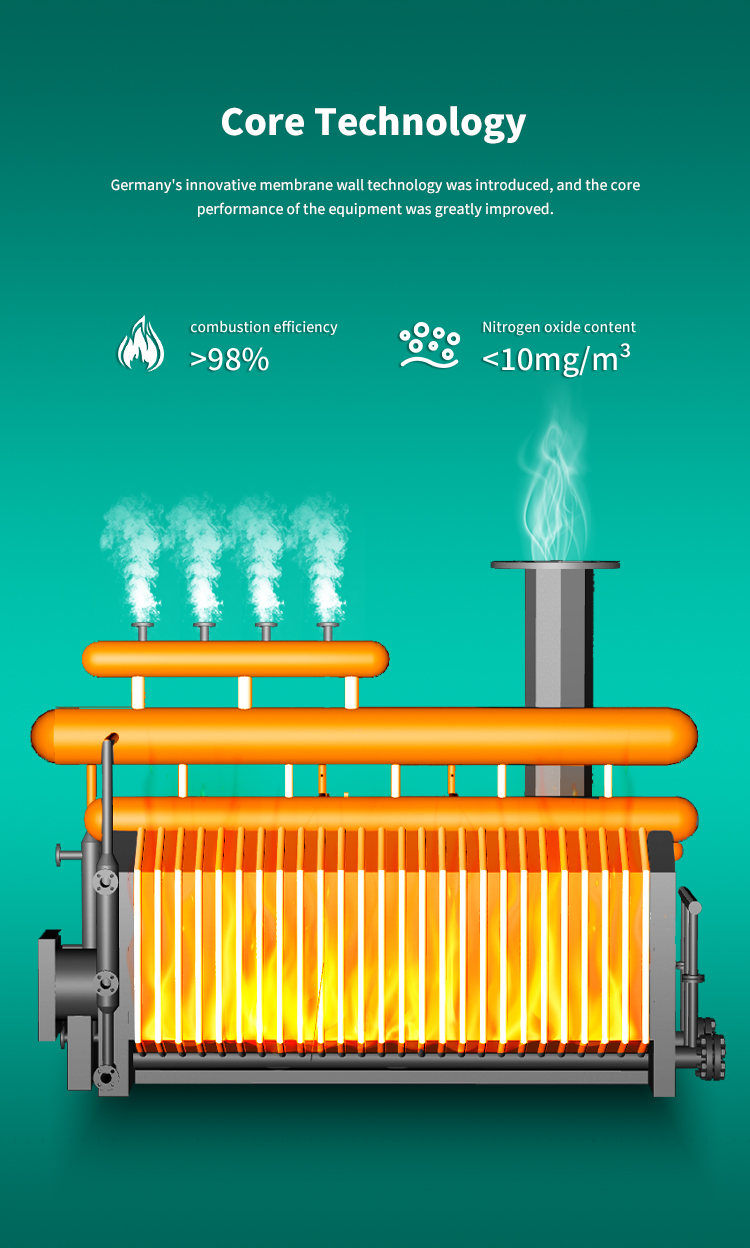

3. Xaiv cov khoom tseem ceeb ntawm cov khoom siv hluav taws xob zoo siab: siv cov hlau tsis muaj steel los ua cov hluav taws xob cua sov lub raj, uas yog 30% ntev tshaj li 304 stainless hlau raj, uas ua kom lub neej kev pab cuam ntawm lub tshuab hluav taws xob cua sov raj zoo, thiab cov thermal efficiency nce mus txog 98%. Nws yog qhov yooj yim rau kev hloov pauv tom qab, kho thiab txij nkawm ua haujlwm, thiab lub tshuab hluav taws xob cua sov yog txuas nrog lub tshuab hluav taws xob lub cev thiab flange.

4. Kev xaiv cov khoom zoo: Tag nrho cov kav dej, cov twj paj nruag, thiab cov ntsuas tau txuas nrog cov kav hlau tsis muaj steel lossis tooj liab, thiab cov khoom siv hluav taws xob uas muaj npe nrov hauv tsev tau siv los ua kom muaj kev nyab xeeb thiab txhim khu kev qha hauv kev siv txhua hnub, nrog cov khoom siv luxurious.

5. Multi-faceted interlocking kev tiv thaiv kev nyab xeeb muaj nuj nqi: Yuav kom tsis txhob muaj xwm txheej tshwm sim los ntawm kev kub siab ntau dhau, cov khoom tau nruab nrog kev tiv thaiv overvoltage xws li lub siab tswj, thiab kev tiv thaiv dej qis nrog txoj cai kom tsis txhob muaj kev puas tsuaj lossis txawm tias hluav taws xob cua sov. Nws kuj muaj kev tiv thaiv kev ua haujlwm, uas tuaj yeem lav qhov kev nyab xeeb ntawm cov neeg ua haujlwm thiab cov khoom siv.

6. Ib lub khawm pib yog qhov yooj yim thiab yooj yim: tag nrho cov khoom tsim los ntawm peb lub tuam txhab tau dhau los ua qhov kev debugging nruj. Cov neeg siv tsuas yog yuav tsum tau txuas rau lub hwj chim thiab dej qhov chaw. Cov txheej txheem installation.

7. Kev tiv thaiv ib puag ncig thiab txuag hluav taws xob nta: cov roj hlawv yog ib puag ncig zoo, tsis muaj kuab paug tawm thaum lub sijhawm hlawv, thiab cov roj hlawv kuj pheej yig, uas tuaj yeem txuag tau nyiaj ntau ntawm cov khoom siv. Tam sim no nws yog ib qho kev sib raug zoo rau ib puag ncig, txuag hluav taws xob thiab cov cuab yeej zoo ib puag ncig.

Cov khoom qeb

-

E-mail

-

Xov tooj

-

WhatsApp

-

Sab saum toj