NOBETH BH 18KW Double Tubes Fully Automatic Electric Steam Generator is used for Steam Health

When concrete is poured within a few days, a large amount of hydration heat will be generated, which will cause the internal temperature of the concrete to rise, which may cause a large temperature difference between the inside and outside, leading to cracks in the concrete. Therefore, bridge steam curing can accelerate the improvement of concrete strength and eliminate surface cracks.

Intelligent variable temperature steam curing control system for bridge steam curing

After the introduction of this production line and the use of Nobis steam generators, prefabricated beam production has become intelligent, factory-based, and intensive. While reducing personnel input, production efficiency has been greatly improved.

The temperature in the region continues to drop, and the temperature at night may even drop below 0°C. At 0 to 4°C, the reaction time of cement hydration is more than three times longer than normal temperature. In this case, the T-beam concrete will not reach 85% of the design strength within 7 days and cannot be prestressed. If the weather is allowed to “run rampant”, it will seriously restrict the production progress of T-beams. At the same time, because the temperature is too low, the cement hydration reaction is slow, which may cause quality problems such as insufficient strength of T-beams.

In order to solve the negative impact of lowering temperatures, it was decided to introduce and upgrade steam curing technology. The high-temperature steam generated by the intelligent steam generator is used to heat the concrete components and maintain a constant temperature and humidity of the beam during the curing period, thereby ensuring Concrete strength and engineering quality.

After the T-beam concrete is poured, first cover it with a layer of shed cloth, and then start the steam generator to ensure that the temperature in the shed is higher than 15°C. The prefabricated T-beam will also feel the warmth and its strength will increase accordingly. Since the adoption of this technology, the production efficiency of T-beams has been greatly accelerated, and the output has reached 5 pieces per day.

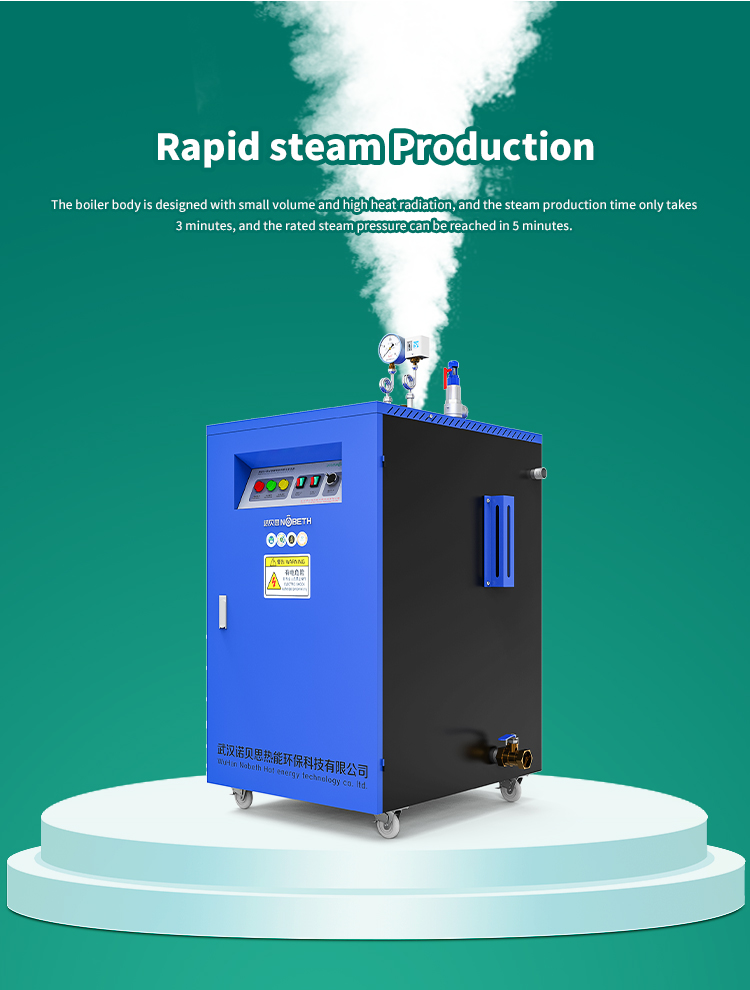

Using a steam generator to steam cure prefabricated beams is called a steam curing machine. The heat generated by the steam curing machine has high thermal efficiency and fast gas production. It is convenient for installation and maintenance. It is equipped with universal casters and is easy to move. The pressure of the equipment has been adjusted at the factory. It can be used after it is connected to water and electricity at the construction site. No complicated installation is required.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top