NOBETH CH 36KW Fully Automatic Electric Steam Generator used for Cement Maintenance in winter

First of all, let me share with you the principle of demoulding of cement pipes. I believe many people know that during the production process of cement pipes, workers will pour cement into the mold, and the cement will solidify and form cement pipes. If it solidifies naturally, it will not only It will cause blistering and cracks to form in the cement pipeline, and the natural solidification time is very long. Therefore, we need to use external force to improve the quality and production efficiency of the cement pipeline. The key to affecting the solidification of the cement pipeline is the ambient temperature. In other words, Just put the molded cement pipe into a constant-temperature space, and its demoulding efficiency will be greatly improved, and the quality of the cement pipe will also skyrocket. The function of the cement pipe demoulding steam generator is to heat up.

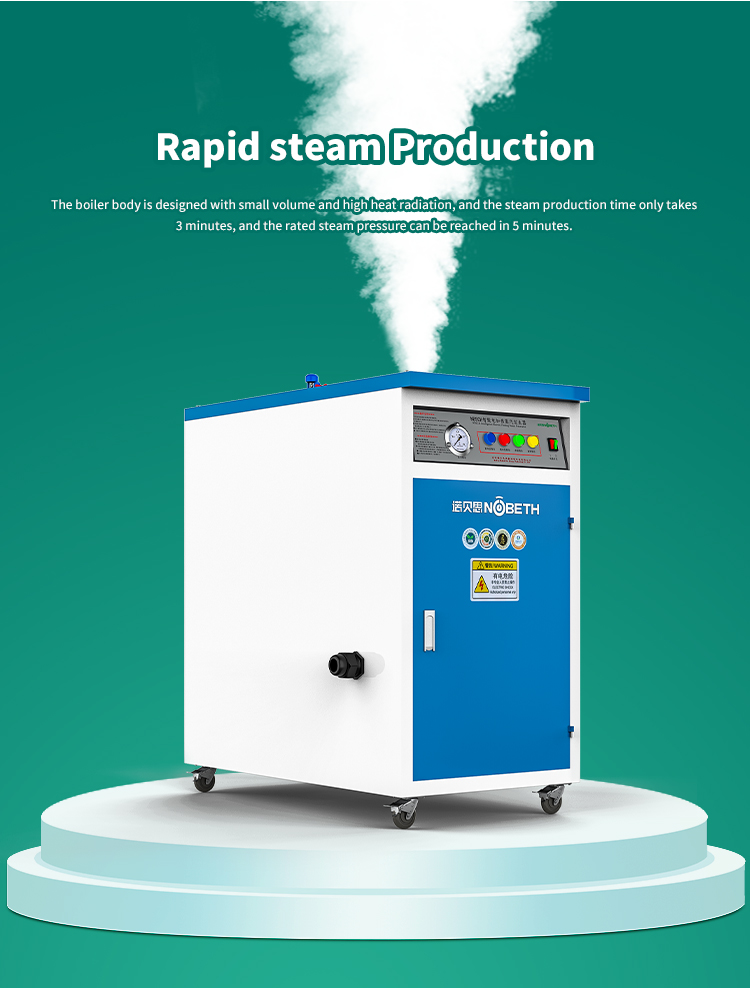

Secondly, let’s talk about cement pipe demoulding equipment. For large cement pipe demoulding companies, we generally recommend electric heating cement pipe demoulding steam generators. Nobest’s cement pipe demoulding steam generator is quite small in size and easy to move. It can be moved between multiple steam curing rooms. Secondly, it generates steam very quickly, about 3- High-temperature steam can be generated in 5 minutes, which is of great help to the efficiency of demoulding cement pipes. More importantly, the operation method is simple and anyone can easily get started.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top