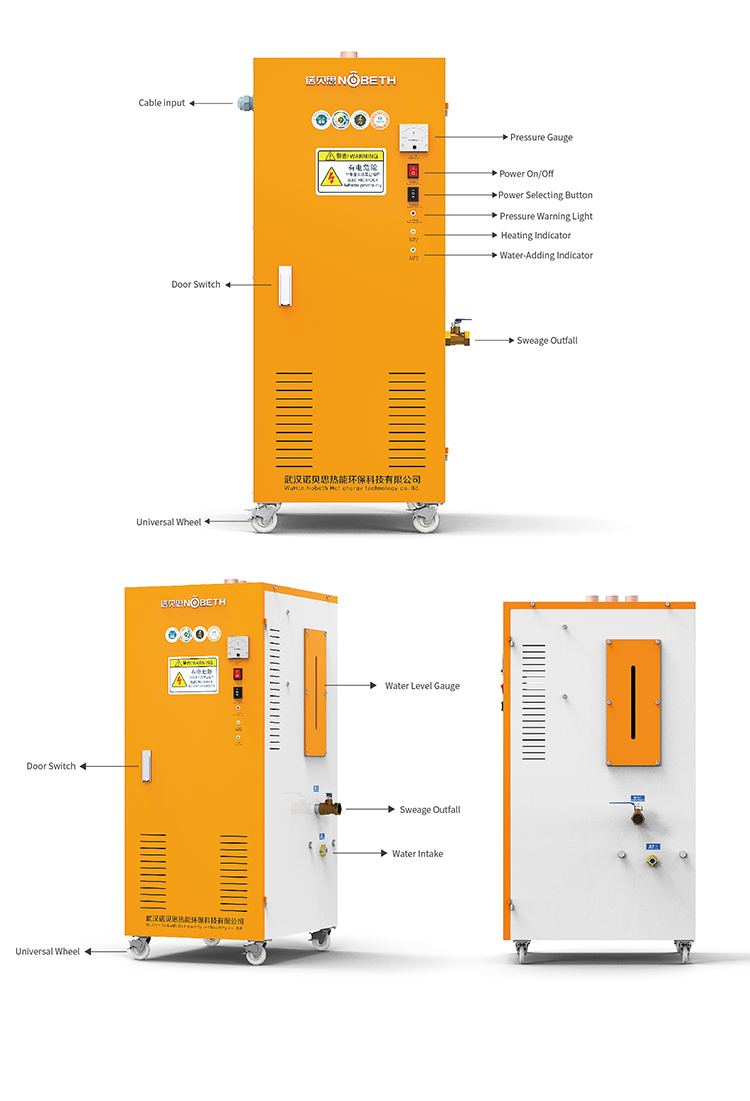

NOBETH GH 18KW Double Tubes Fully Automatic Electric Steam Generator is used for Emulsification Technology

However, as a cosmetic, it requires a variety of functions and properties, which requires equipment with a steam generator to heat and humidify and control the emulsification temperature to prepare an emulsion with excellent and stable properties.

The use of steam generators supporting emulsification equipment is of extremely important significance to the research, production, preservation and use of cosmetics. In emulsification, it is not only necessary to meet the stirring conditions, but also to control the temperature during and after emulsification. For example, the stirring intensity and the amount of emulsifier will affect the size of the emulsion particles, and the stirring intensity can replace the addition of emulsifier during emulsification, and the more vigorous the stirring, the lower the amount of emulsifier.

Due to the influence of temperature on the solubility of emulsifiers and the melting of solid oil, grease, wax, etc., temperature control during emulsification determines the emulsification effect. If the temperature is too low, the solubility of the emulsifier is low, and the solid oil, grease, and wax are not melted, and the emulsification effect is poor; if the temperature is too high, the heating time is long, resulting in a correspondingly longer cooling time, which wastes energy and lengthens the production cycle. The temperature and pressure of the steam generator equipped with the equipment are adjustable, which not only avoids poor low-temperature emulsification effect, but also controls the cost and time consumption caused by high temperature.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top