NOBETH GH 48KW Double Tubes Fully Automatic Electric Steam Generator is used for Hospital Laundry Equipment

Generally, when laundry rooms and washing plants purchase washing equipment, they hope to be equipped with steam-type washing equipment. Whether it is a dryer or an ironing machine, the use of steam washing equipment has gradually become an industry consensus. Many washing equipment are equipped with steam interfaces. Let’s analyze the role of steam in the washing process.

Hospital washing equipment is used for washing, dehydrating, disinfecting and sterilizing various hospital gowns, sheets, pillowcases, quilt covers and other linens in the hospital. Large hospital laundry room washing equipment mainly provides daily washing and disinfection of linens inside the hospital. It can be washed and disinfected directly in the hospital laundry room, and then put into use in the ward. The hospital laundry room serves as a logistics support unit, and the steam generator The supporting laundry room equipment provides guarantee for the supply of linen for each unit of the hospital.

1. High-temperature sterilization: Washing equipment uses steam to perform high-temperature sterilization to kill bacteria on clothes to meet health requirements.

2. Reduce the wear and tear of clothes: Use steam for washing to improve the washing performance, reduce the washing time of clothes and linens, and minimize the wear and tear of clothes in the hospital.

3. Reduce clothing damage: Washing equipment uses high-temperature steam for washing, which can effectively prevent high-end clothing from deforming or wrinkling.

4. Save energy consumption: Compared with ordinary washing methods, the use of steam generators with dryers, ironing machines and other equipment can greatly shorten washing time and effectively save water and electricity.

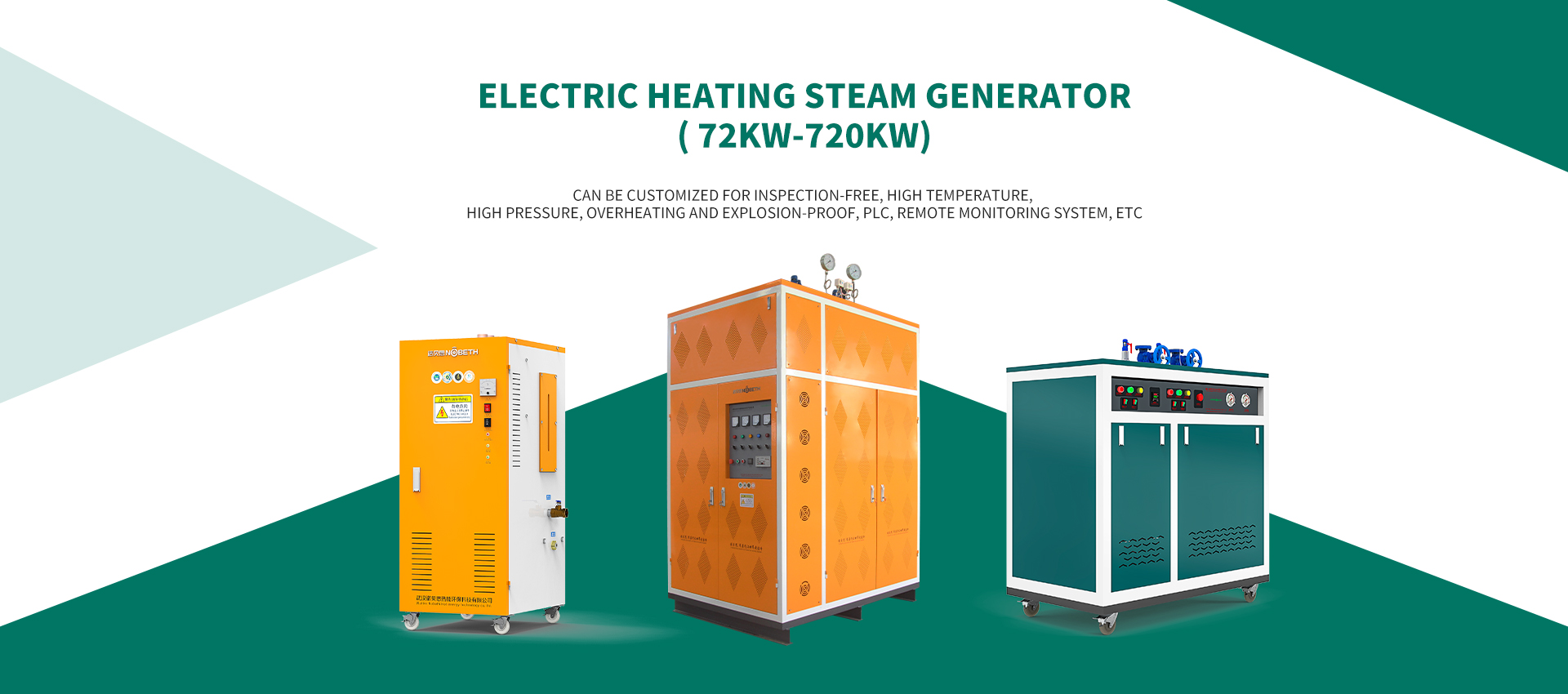

Nobeth steam generators come in a wide variety of sizes and models and can be customized. It is recommended to purchase under the guidance of the manufacturer. In addition, because the steam generator is a special equipment with a normal water volume of 29L, it is not within the scope of the supervisory inspection of the “Pot Regulations”. One machine has one certificate, and there is no need for a certified boiler to be on duty, which solves the problem of logistics management. After purchase, it can be used immediately with electricity and water. Report installation.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top