Koronto dhaliyaha uumku waa mid ka mid ah qalabka tamarta ee loo isticmaalo wax soo saarka waana nooc ka mid ah qalabka gaarka ah. Matoorada uumiga waxaa loo isticmaalaa dhinacyo badan oo nolosheena ah waxayna si dhow ula xiriiraan dharkeena, cuntadeena, guriyeynta, gaadiidka iyo dhinacyo kale. Si loo habeeyo naqshadaynta iyo isticmaalka matoorrada uumiga, hawshoodana looga dhigo mid badbaado leh oo la isku halayn karo, waaxyaha ay khusayso waxay dejiyeen xeerar badan oo khuseeya si dab-dhaliyeyaashu ay si wanaagsan uga faa'iidaystaan nolosheena.

1. Goobaha codsiga ee matoorayaasha uumiga

Dharkadhar-xoqida, mishiinada nadiifinta qalajinta, qalajiyaha, mishiinada dharka, fuuq-baxayaasha, mishiinada kafeega, birta iyo qalabyada kale ayaa la isticmaalaa iyaga oo la socda.

Cuntada:Bixi qalab taageeraya cabitaanka biyaha la karkariyey, cunto karinta, soo saarista baasto bariiska, caanaha soy ee karkaraya, mishiinada tofu, sanaadiiqda bariiska ee uumi, haamaha jeermis dilaha, mishiinada baakadaha, mashiinada calaamadaynta gacmaha, qalabka dahaadhka, mashiinada wax lagu xidho, nadiifinta alaabta miiska iyo qalab kale.

Hoyga:kululaynta qolka, kulaylka dhexe, kululaynta sagxada, kulaylka dhexe ee bulshada, qaboojiyaha kaaliyaha ah (bamka kulaylka) kululaynta, biyo kulul oo leh tamarta cadceedda, (huteelada, qolalka jiifka, dugsiyada, xarumaha isku dhafka) sahayda biyaha kulul, (buundooyinka, jidadka tareenada) dayactirka la taaban karo, (Naadiga quruxda wakhtiga firaaqada) saunada qubeyska, warshadaynta alwaax, iwm.

Warshadaha:nadiifinta baabuurta, tareenada iyo baabuurta kale, dayactirka waddooyinka, warshadaha rinjiyeynta, iwm.

2. Tilmaamaha la xidhiidha dhaliyaasha uumiga

Soosaarayaasha uumiga ayaa door muhiim ah ka ciyaara wax soo saarka warshadeena, badqabka wax soo saarkooduna waxa uu xidhiidh dhow la leeyahay nolol maalmeedka. Sidaa darteed, marka qalabka la soo saarayo, waa in aan si adag u xakameyno wax soo saarka, u hoggaansanaana xeerarka khuseeya, oo soo saara qalab ammaan iyo waxtar leh oo la xiriira.

Oktoobar 29, 2020, "Xeerarka Farsamada Farsamada Badbaadada Kuleyliyaha" (TSG11-2020) (halkan ka dib loogu yeero "Xeerarka kululeeyaha") waxaa ansixiyay oo uu faafiyay Maamulka Gobolka ee Xeerka Suuqa.

Xeerkani wuxuu isku daraa "Xeerarka Ilaalinta Farsamada ee Badbaadada Boiler" (TSG G0001-2012), "Sharciyada Maareynta Qiimaynta Dukumentiga Naqshadaynta" (TSG G1001-2004), "Shidaalka (Gaaska) Xeerarka Farsamada Badbaadada Gubida" (TSG ZB001-2008) , "Test 2008". ZB002-2008), " Xeerarka Nadiifinta Kiimikada kululeeyaha" (TSG G5003-2008), "Koontaroolka iyo Xeerarka Maareynta Kuleyliyaha Biyaha (dhexdhexaad) iyo Xeerarka Kormeerka" (TSGG7001-2015), "Sharciyada Kormeerka Xilliga Kuleylaha" (TSG G7002-2015) Isku-dubarid si loo sameeyo tilmaamo farsamo oo dhamaystiran oo loogu talagalay kuleyliyeyaasha.

Marka la eego agabka, sida ku xusan shuruudaha cutubka 2, qodobka 2aad ee "Xeerarka Karinta": (1) Qalabka birta ee qaybaha cadaadiska ee kuleyliyaha iyo qaybaha culeyska ee lagu dhejiyo qaybaha cadaadiska waa in la dilo; (2) Qalabka birta ah ee qaybaha cadaadiska ee kuleyliyaha (kabka heerkulka qolka Charpy saamaynta tamarta nuugo (KV2) waa in aanay ka yarayn 27J (marka laga reebo qaybaha birta);

Marka la eego naqshadeynta, qodobka 1 ee cutubka 3 ee "Xeerarka Karinta" wuxuu dhigayaa in naqshadeynta kuleyliyeyaasha ay tahay inay buuxiyaan shuruudaha badbaadada, badbaadinta tamarta iyo ilaalinta deegaanka. Qaybaha wax soo saarka kuleyliyaha ayaa mas'uul ka ah tayada naqshadeynta alaabta kuleyliyaha ay soo saaraan. Marka la nashqadeynayo kuleyliyaha iyo nidaamkiisa, nidaamka waa in la hagaajiyaa iyadoo lagu saleynayo waxtarka tamarta iyo shuruudaha qiiqa wasakhowga hawada, iyo cabbirrada farsamo ee la xiriira sida diiradda qiiqa bilowga ah ee wasakhowga hawada waa in la siiyaa isticmaalaha kuleyliyaha.

Dhanka wax-soo-saarka, qodobka 1-aad ee cutubka 4-aad ee "Xeerarka Kariinka" wuxuu dhigayaa: (1) Qaybaha wax-soo-saarka kululeeyaha waxay mas'uul ka yihiin badbaadada, badbaadinta tamarta, waxqabadka ilaalinta deegaanka iyo tayada wax-soo-saarka badeecooyinka ka baxaya warshadda, loomana oggola inay soo saaraan badeecooyinka kuleyliyaha ah ee ay dowladdu baabi'isay; (2) Soosaarayaasha kuleyliyaha Cilladaha waxyeelada leh waa in aan la soo saarin ka dib marka la gooyo walxaha ama habaynta, iyo qaybaha cadaadiska ayaa la sameeyay. Qabow samaynta waa in ay ka fogaato adkaanta shaqada qabow ee sababa jab jaban ama dildilaac. Samaynta kulul waa in ay ka fogaato cilladaha waxyeelada leh ee ay sababto heerkul aad u sarreeya ama aad u hooseeya. ; (3) Dib-u-habaynta alxanka ee qaybaha birta ah ee loo isticmaalo qaybaha cadaadiska-sida lama ogola; (4) Tuubooyinka ku dhex jira baaxadda kuleyliyaha saldhigga korontada, heerkulka iyo qalabka dhimista cadaadiska, mitirka socodka (kacyada), qaybaha tuubooyinka prefabricated ee warshadda iyo qaybaha kale ee isku dhafan waa in ay ahaadaan kormeerka wax soo saarka iyo kormeerka waa in lagu fuliyaa si waafaqsan shuruudaha qaybaha kuleyliyaha ama isku-dhafka qaybaha tuubooyinka cadaadiska; xirmooyinka tuubooyinka waa in ay hoos yimaadaan kormeerka wax soo saarka iyo kormeerka iyadoo la raacayo shuruudaha ku habboon qaybaha kuleyliyaha ama tijaabada nooca waa in lagu fuliyaa si waafaqsan shuruudaha khuseeya qaybaha tuubooyinka cadaadiska; tuubooyinka birta, valves, magdhowyada iyo qaybaha kale ee tuubooyinka cadaadiska, nooca tijaabada waa in lagu sameeyaa si waafaqsan shuruudaha ku habboon qaybaha tuubooyinka cadaadiska.

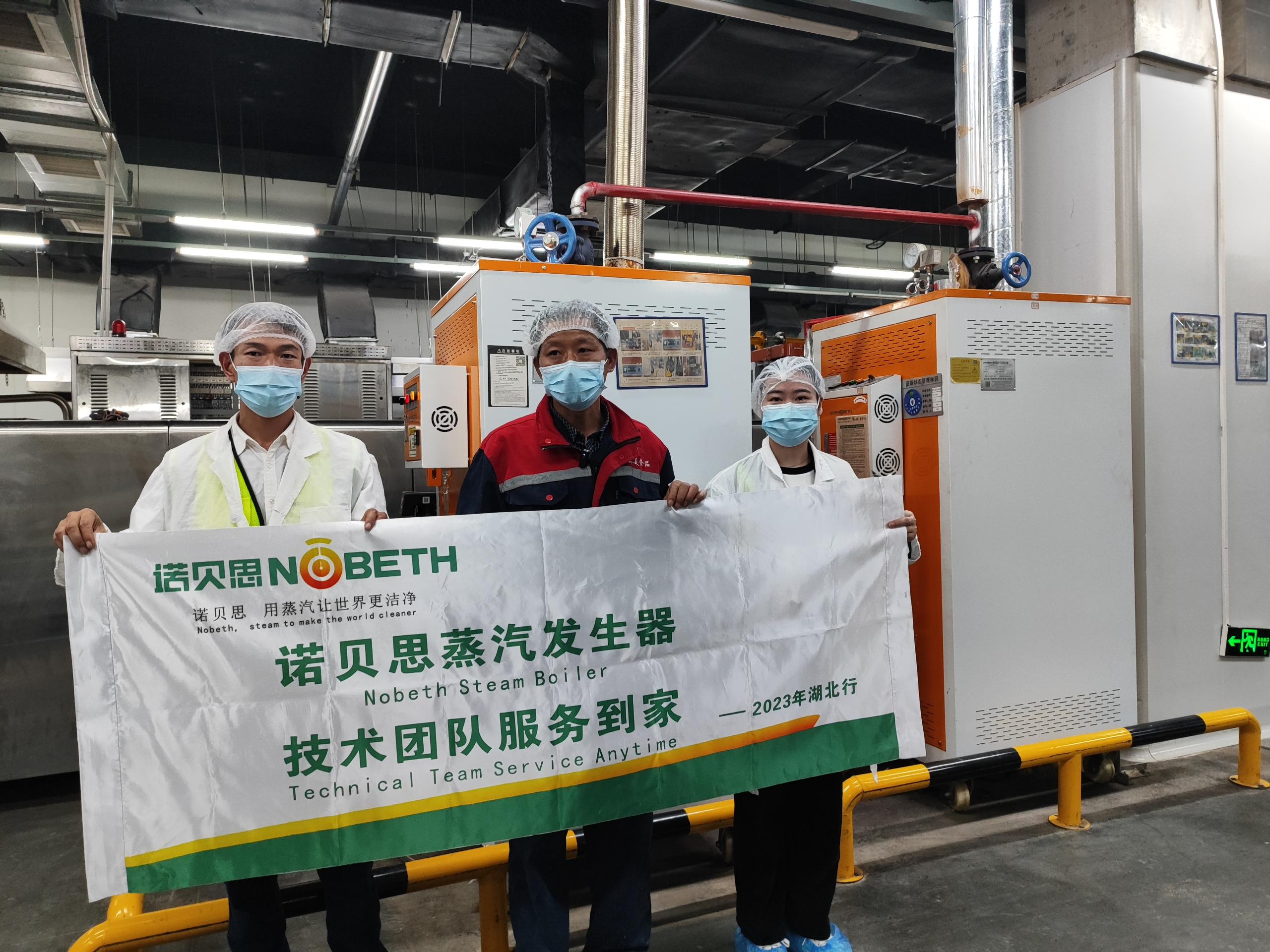

3. Nobeth uumi dhaliye

Wuhan Nobeth Thermal Environmental Technology Technology Co., Ltd., oo ku taal badhtamaha bartamaha Shiinaha iyo marinka sagaal gobol, wuxuu leeyahay 23 sano oo waayo-aragnimo ah wax soo saarka tamarta uumiga wuxuuna siin karaa isticmaalayaasha xalal dhammaystiran oo kululeeyaha uumiga oo ay ku jiraan xulashada, wax soo saarka, gaadiidka, iyo rakibidda. Marka naqshadaynta iyo soosaarka qalabka uumiga ee la xidhiidha, Nobeth si adag u fuliyaa xeerarka qaranka ee khuseeya, nuugaya waayo-aragnimada horumarsan ee gudaha iyo dibaddaba, si joogto ah u fulisa hal-abuurnimada tignoolajiyada iyo dib-u-habaynta, waxayna soo saartaa qalab horumarsan oo buuxiya shuruudaha wakhtiyada.

Nobeth Steam Generator wuxuu si adag u maamulaa dhammaan isku xirka wax soo saarka, wuxuu raacaa qawaaniinta qaranka, wuxuuna qaataa ilaalinta tamarta, ilaalinta deegaanka, hufnaanta sare, badbaadada, iyo kormeerka xorta ah sida shanta mabaadi'da asaasiga ah. Waxa ay si madaxbanaan u soo saartay koronto dhalisa uumiga kuleyliyaha oo dhamaystiran , Matoorrada uumiga shidaalka si buuxda otomaatig ah, deegaanka u saaxiibka ah koronto-dhaliyeyaasha uumiga, matoorrada uumiga ee aan qarxin, matoorrada uumiga kulul, matoorrada uumiga-cadaadiska sareeyo iyo in ka badan 200 oo badeecado ah oo ka badan toban taxane, tayadooda iyo tayadooda waxay u istaagi karaan Imtixaanka waqtiga iyo suuqa.

Waqtiga boostada: Nov-16-2023