I-0.3T I-Gas kanye Ne-Oil Energy Saving Steam Boiler

Isistimu yesitimu enhle neyonga amandla ihlanganisa yonke inqubo yokuklama isistimu yesitimu, ukufakwa, ukwakhiwa, ukunakekelwa, kanye nokwenza kahle. Okuhlangenwe nakho kwe-Watt Energy Saving kubonisa ukuthi amakhasimende amaningi anamandla amakhulu namathuba okonga amandla. Amasistimu we-steam athuthukisiwe njalo anakekelwa angasiza abasebenzisi besitimu behlise ukumosheka kwamandla ngo-5-50%.

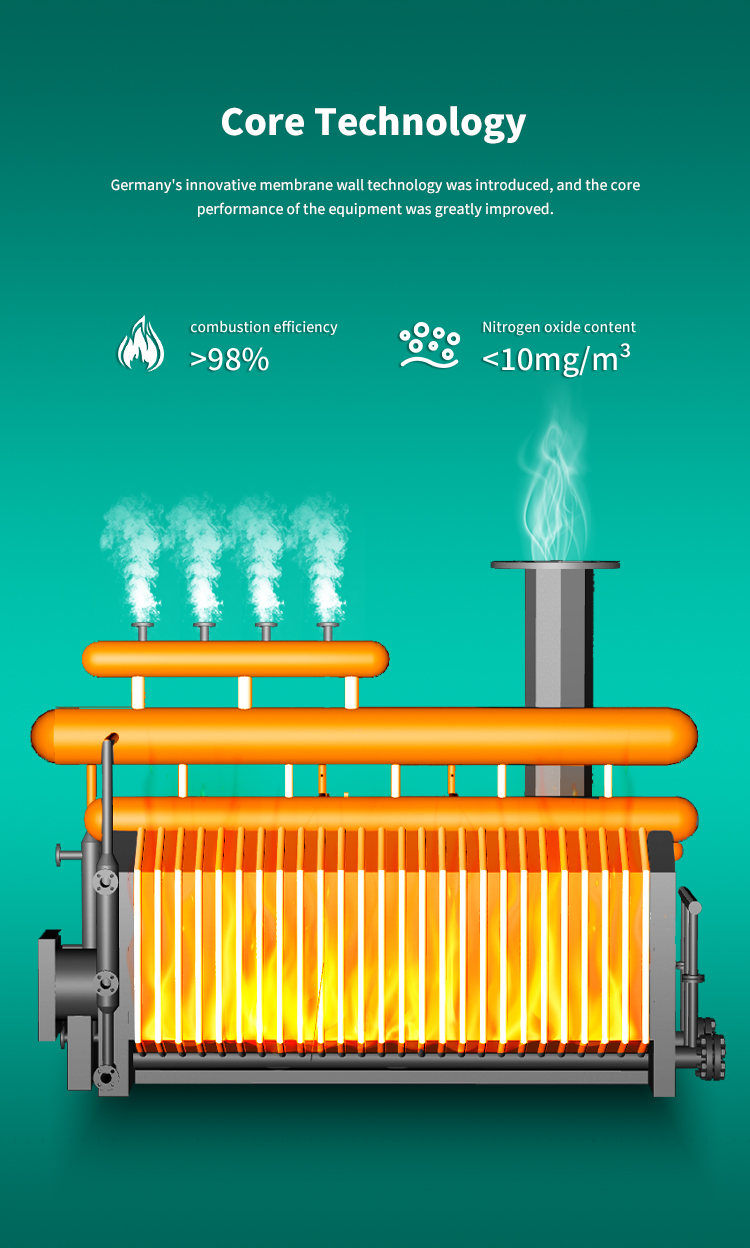

Ukusebenza kahle kokuklama kwama-boilers we-steam kungcono ngaphezu kwama-95%. Kunezici eziningi ezithinta ukumosheka kwamandla kabhayela. I-Steam carryover (amanzi athwala umusi) yingxenye evamise ukunganakwa noma engaziwa abasebenzisi. I-5% ye-carryover (evame kakhulu) isho ukuthi ukusebenza kahle kwebhayela kuncipha ngo-1%, futhi amanzi athwala isitimu azodala Ukwenyuka kokugcinwa nokulungiswa kwalo lonke uhlelo lwesitimu, ukukhishwa okuncishisiwe kwemishini yokushintshanisa ukushisa kanye nezidingo zokucindezela okuphezulu.

Ukufakwa kahle kwamapayipi kuyisici esibalulekile ekwehliseni imfucumfucu yesitimu, futhi kubalulekile ukuthi izinto ezifakwa ngaphakathi zingaboli noma zicwiliswe ngamanzi. Ukuvikelwa okufanele kwemishini nokuvimbela amanzi kuyadingeka, ikakhulukazi ukufakwa kwangaphandle. Ukulahleka kokushisa okuvela ekufakweni okumanzi kuzoba izikhathi eziphindwe ka-50 lapho kuhlakazeka kahle emoyeni.

Iziteshi zamavalvu amaningana anamathange okuqoqa amanzi kufanele zifakwe eduze kwepayipi lesitimu ukuze kubonakale ukususwa ngokushesha nangokuzenzakalelayo kwe-condensate yesitimu. Amakhasimende amaningi akhetha izicupho ezishibhile zohlobo lwediski. Ukususwa kwesicupho sohlobo lwe-disc kuncike kwijubane lokujiya legumbi lokulawula phezulu kwesicupho se-steam, kunokuba kususwe amanzi e-condensate. Lokhu kubangela ukuthi kungabi nesikhathi sokukhipha amanzi lapho amanzi edingeka, futhi Ngesikhathi sokusebenza okuvamile, isitimu siyamoshakala lapho kudingeka ukugeleza kwamanzi. Kungabonakala ukuthi izicupho ze-steam ezingafaneleki ziyindlela ebalulekile yokubangela imfucumfucu.

Kuhlelo lokusabalalisa umusi, kubasebenzisi be-steam ngezikhathi ezithile, lapho umusi umiswa isikhathi eside, umthombo we-steam (njenge-boiler room sub-cylinder) kufanele unqunywe. Emapayipini asebenzisa isitimu ngezikhathi ezithile zonyaka, amapayipi esitimu azimele kufanele asetshenziswe, futhi amavalvu okumisa ama-bellows-sealed (DN5O-DN200) kanye namavalvu ebhola asezingeni eliphezulu (DN15-DN50) asetshenziswa ukuze kunqandwe ukunikezwa ngesikhathi sokunqamuka kwesitimu.

I-valve yokudonsa yesishintshi sokushisa kufanele iqinisekise ukugeleza okukhululekile nokubushelelezi. Isishintshi sokushisa singakhethwa ukuze sisebenzise ukushisa okunengqondo kwesitimu ngangokunokwenzeka, sehlise izinga lokushisa lamanzi ajiyile, futhi sinciphise amathuba okuba khona kwe-flash steam. Uma ukugeleza okugcwele kuyadingeka, ukubuyiswa nokusetshenziswa kwe-flash steam kufanele kucatshangelwe.

Amanzi ajiyile ngemva kokushintshana kokushisa kufanele atholakale ngesikhathi. Izinzuzo zokubuyiswa kwamanzi e-condensate: Buyisa ukushisa okunengqondo kwamanzi e-condensate aphezulu ukuze wonge uphethiloli. Uphethiloli weboiler ungonga cishe ngo-1% kukho konke ukukhuphuka kwezinga lokushisa kwamanzi ngo-6°C.

Sebenzisa ubuncane benombolo yamavalvu okwenziwa ngesandla ukuze ugweme ukuvuza kwesitimu nokulahlekelwa ukucindezela, futhi wengeze isibonisi esanele nezisetshenziswa zezinkomba ukuze wahlulele isimo namapharamitha esitimu ngesikhathi. Ukufaka amamitha okugeleza kwesitimu anele kungaqapha ngempumelelo izinguquko kumthwalo wesitimu futhi kubone ukuvuza okungase kube khona ohlelweni lwesitimu. Amasistimu e-steam kufanele aklanywe ukunciphisa ama-valve angasasebenzi kanye nokufakwa kwamapayipi.

Uhlelo lwesitimu ludinga ukuphathwa nokugcinwa kahle kwansuku zonke, ukusungulwa kwezinkomba zobuchwepheshe ezifanele kanye nezinqubo zokuphatha, ukunakwa kobuholi, ukuhlola inkomba yokonga ugesi, ukukalwa kahle kwesitimu kanye nokuphathwa kwedatha kuyisisekelo sokunciphisa udoti.

Ukuqeqeshwa nokuhlolwa kokusebenza kwesistimu yesitimu kanye nabasebenzi bokuphatha kuwukhiye wokonga amandla esitimu kanye nokunciphisa ukumosheka kwesitimu.

Izigaba zemikhiqizo

-

I-imeyili

-

Ucingo

-

WhatsApp

-

Phezulu