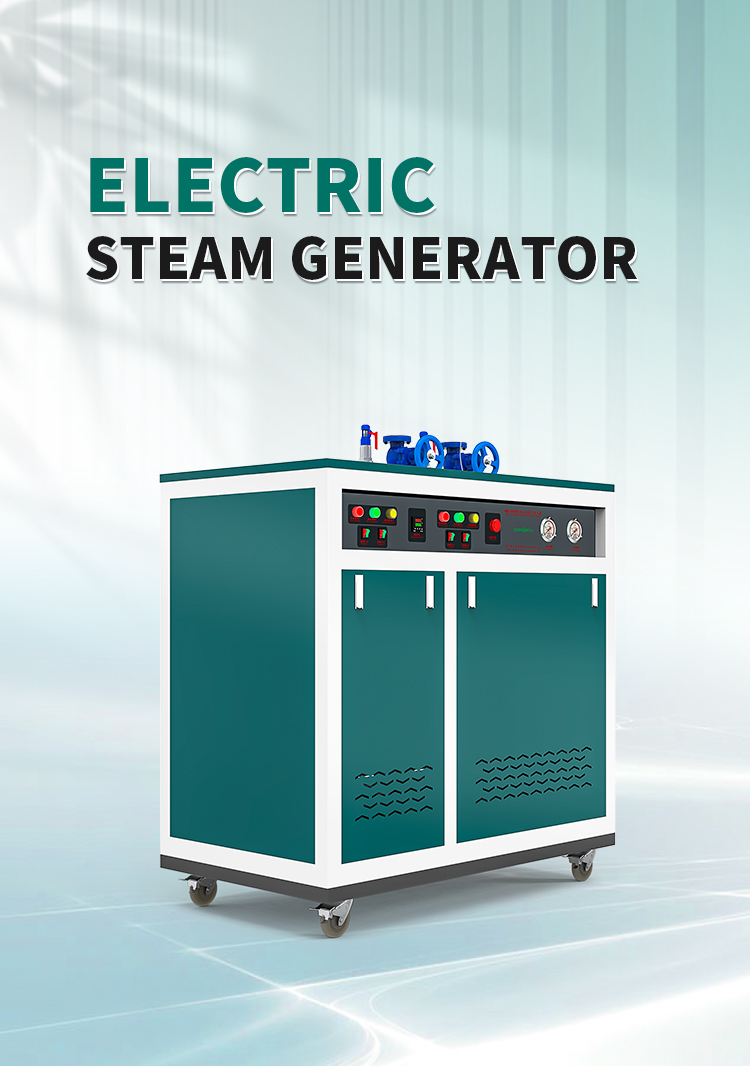

180kw Electric Steam Generator for Wine Distillation

Ukupheka okusanhlamvu, isidingo se-steam kufanele sibe sikhulu futhi sifane, ukuze kuqinisekiswe ukuthi okusanhlamvu kuyashiswa ngokulinganayo futhi kuphekwe. Asikho isidingo sokucindezela ku-steam. Izinga lokushisa lilingana ngqo nengcindezi. Uma izinga lokushisa liphakeme, umfutho we-steam mkhulu futhi okusanhlamvu kuzoshunqa ngokushesha. Okugxilwe lapha kusekuhambeni kweshaneli yesitimu kuqinisekisa ukuthi okusanhlamvu kushisisa ngokulinganayo. Izinto ezisetshenziswa ngesitimu zingakhethwa ngokuya ngenani eliphezulu lokusanhlamvu okushisiwe okudingekayo ekukhiqizweni kanye nesidingo sesimusi sosayizi wesitsha. Ingcindezi yesitimu engu-0.4MPA~0.5MPA yanele ngokuphelele.

Izinga le-saccharification lithinta ngokuqondile isivuno sotshwala. Ukulungiswa kwezinga lokushisa le-saccharification kanye nesikhathi se-saccharification ikakhulukazi kusekelwe kukhwalithi ye-malt, isilinganiso sezinto ezisizayo, isilinganiso samanzi wezinto ezibonakalayo, ukwakheka kwe-wort, njll. Isimo sihlukile, futhi akukho ukujwayelekile. setha imodi. Abenzi bewayini abanolwazi bazosetha i-saccharification engashintshi kanye nezinga lokushisa lokuvutshelwa ngokusekelwe kokuhlangenwe nakho. Isibonelo, izinga lokushisa lekamelo lokuvutshelwa lingama-degree angu-20-30, futhi izinga lokushisa lezinto zokuvutshelwa alidluli ama-36 degrees. Ngaphansi kwezimo zokushisa eziphansi ebusika, umthelela wokulawula izinga lokushisa okunembile kanye nokuswakama okungaguquki kwezinga lokushisa kungafinyelelwa ngemishini yesitimu.

Iwayini elicwecwe liyiwayini lokuqala elikhiqizwayo. Kusetshenziswa umehluko phakathi kwendawo yokubilisa yotshwala (78.5°C) nendawo abilayo yamanzi (100°C), umhluzi wokuqala wokubilisa ushiswa phakathi kwamaphoyinti amabili abilayo ukuze kukhishwe utshwala obusezingeni eliphezulu nephunga elimnandi. isici. Isimiso sokukhishwa kwe-distillation kanye nenqubo: Indawo yokuhwamuka kotshwala ngu-78.5°C. Iwayini langempela liyashisisa libe ngu-78.5°C futhi ligcinwe kulelizinga lokushisa ukuze lithole utshwala obuhwamukile. Ngemva kokuba utshwala obuhwamukile bungene epayipini futhi buphole, buba utshwala obuwuketshezi. Kodwa-ke, ngesikhathi sokushisisa, izinto ezinjengomswakama noma isitimu esingcolile ezintweni ezingavuthiwe nazo zizohlanganiswa notshwala, okuholela kumawayini ekhwalithi ehlukene. Amawayini amaningi adumile asebenzisa izinqubo ezahlukene ezifana ne-distillation eminingi noma i-wine heart extraction ukuze athole amawayini anobumsulwa obuphezulu nokuqukethwe okuphansi kokungcola.

Inqubo yokupheka, i-saccharification kanye ne-distillation ayinzima ukuyiqonda. I-distillation yewayini idinga umusi. Isitimu sihlanzekile futhi sihlanzekile, siqinisekisa izinga lewayini. Isitimu siyalawuleka, izinga lokushisa liyalungiseka, futhi isilawuli sinembile, siqinisekisa ukupheka okulula nokusebenza kokukhishwa kwe-distillation. Ngokombono wokukhiqiza nokusebenza, okokusebenza kokusetshenziswa kwamandla esitimu kanye nokonga amandla kuyizihloko abasebenzisi abakhathazeke ngazo kakhulu.

Ijeneretha yesitimu entsha ichitha umgomo ovamile wokukhipha isitimu. Ipayipi lingena emanzini likhiphe isitimu. Ingasetshenziswa ngokushesha ngemva kokuqala, ngokusebenza kahle kokushisa okuphezulu. Awekho amanzi, i-steam ihlanzekile futhi ihlanzekile, futhi ukubilisa okuphindaphindiwe kwamanzi angcolile kuyaqedwa, futhi inkinga yesikali iphinde iqedwe, futhi impilo yesevisi yemishini inwetshiwe. Umthelela wokonga amandla u-50% wezinto ezisetshenziswa isitimu kagesi kanye no-30% wezinto zokusebenza zegesi. Ukusebenza kahle okuphezulu, ukonga amandla nokuvikelwa kwemvelo!

Izigaba zemikhiqizo

-

I-imeyili

-

Ucingo

-

WhatsApp

-

Phezulu