I-NBS GH 48KW Fully Automatic Electric Heating Steam Generator esetshenziselwa Inqubo Yokwelashwa Kwe-Steel Steam Oxidation

Esithandweni esiziklanyelwe sona sokwelapha isitimu, kwacutshungulwa inqubo yokwelapha umusi yensimbi evamile evame ukusetshenziswa engu-45#, futhi indlela yokuklwebheka, i-X-ray, i-SEM nezinye izindlela zasetshenziswa ukutadisha amandla okubopha, ukujiya, ukwakheka kanye nokwakheka kwefilimu ye-oxide egcwele umusi. Izici ezihlobene.

Imiphumela ibonisa ukuthi inqubo yokwelashwa kwe-steam efanelekile ukushisa ku-570 ° C, ibambe amahora angu-3, futhi idonsa amanzi ku-0.175ml/min. Amandla okuxhumana nefilimu anamandla kunenqubo evamile yokwenza mnyama. Kodwa-ke, ukuminyana kwefilimu ye-oxide efakwe umusi kubi kakhulu kunaleyo emnyama, futhi umthwalo obalulekile uyancipha njengoba isikhathi sokubamba sikhuphuka ngaphansi kwezinga lokushisa elifanayo kanye nenani eliconsayo.

Kuyini ukwelashwa ngesitimu? Yiziphi izingxenye ezifanele ukucutshungulwa? Okubizwa ngokuthi ukwelashwa kwesitimu kuyinqubo lapho izingxenye zensimbi zishiswa khona ngesitimu esigcwele ku-540 kuya ku-560 ° C ukuze zakhe ifilimu efanayo, eminyene, enozibuthe ye-Fe3O4 enobukhulu obungamamitha angu-2 kuya ku-5 ebusweni bensimbi. Inokumelana okuhle ne-Corrosion kanye nomphumela wokuqeda ukugqwala, kuyilapho ithuthukisa impilo yesevisi yethuluzi.

Ngokombono wokwelashwa ngesitimu, njengoba izinga lokushisa layo lokusebenza lingaphezu kuka-500 ° C, izindleko zayo ziphezulu futhi imishini ekhethekile yokwelapha isitimu iyadingeka. I-Nobis steam generator ingenza ngendlela oyifisayo amajeneretha okushisa aphezulu kanye nokucindezela okuphezulu ukuze akhiqize isitimu esigcwele izinga lokushisa eliphezulu, okuwukwelashwa kwe-Steam yezingxenye zensimbi kungafinyelela imiphumela emihle!

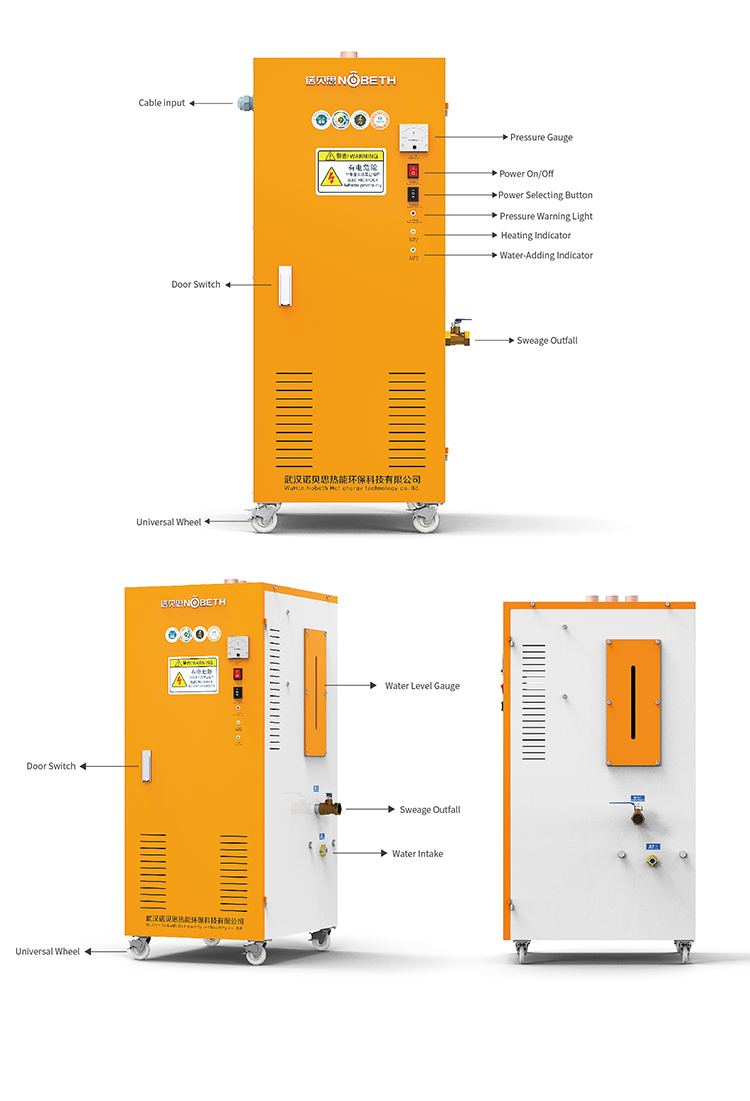

Ukushisa okuphezulu kanye ne-high pressure steam generator

I-Nobeth high lokushisa kanye ne-high pressure steam generator inezinhlobonhlobo zemisebenzi. Ngenxa yezici zayo zokushisa okuphezulu, isetshenziswa kabanzi ezimbonini ezahlukahlukene zokukhiqiza nokucubungula:

① Ukwelashwa ngesitimu kufaneleka kakhulu kunsimbi enesivinini esikhulu kanye namathuluzi ensimbi enziwe ngengxubevange ephezulu. Njengoba izinga lokushisa elipholile lamathuluzi ensimbi enesivinini esikhulu lihambisana nalo, inqubo yokwelapha isitimu nayo iyinqubo yokuthambisa. Ngesikhathi esifanayo, kwakhiwa ifilimu ye-Fe3O4, engathuthukisa ukumelana nokugqwala futhi Ukuphila kwesevisi kungu-20% kuya ku-30%. Ingavimbela ukukhiqizwa kwesikali se-oxide (Fe2O3·FeO) esithandweni somusi, iqinisekise ukunemba kwethuluzi. Insimbi ye-Carbon kanye nensimbi ye-low-alloy ejwayelekile izobangela ukwehla kokuqina kulokhu kushisa, ngakho-ke akufanelekile ukusetshenziswa.

② Ifanele ukwelashwa okungaphezulu kwamashidi ensimbi ye-silicon, angathola inani elikhulu nelifanayo lokumelana, konga upende obalulekile wokuvikela.

③Ifanele ukwelashwa okulwa nokugqwala kanye nokugcwalisa imbobo kwe-powder metallurgy ukuze kuthuthukiswe ubulukhuni bayo namandla acindezelayo.

④Ifanele ukwelashwa okungaphezulu kwamanye ama-workpieces angewona ama-alloy ukuthuthukisa ukumelana nokugqwala.

⑤ Ifanele ukwelashwa okungaphezulu kwezikulufu namantongomane enziwe nge-carbon steel ukuze kuthuthukiswe ukubukeka nekhono lokulwa nokugqwala.

Amajeneretha okushisa aphezulu e-Nobeth kanye ne-high-pressure steam akhiqizwa ngokuhambisana nezindinganiso kazwelonke zomkhumbi wengcindezi. Afakwe amaphampu amanzi anomfutho ophezulu, akwazi ukugcwalisa amanzi uma kunomfutho omkhulu esitsheni. Ziyimiklamo yokumelana nokuqhuma kwengcindezi ephezulu kanye nemiklamo engenasikali. Amandla angalungiswa ngokungenamkhawulo. Kulula ukuzisebenzisa, ziphephile futhi zisebenza kahle!

Izigaba zemikhiqizo

-

I-imeyili

-

Ucingo

-

WhatsApp

-

Phezulu